Thanks to a line designed on a Sysmac platform, Working Process was able to bring together all the processes involved in the machining of windows and doors in a single automated line. All within the required safety parameters.

More than 16 years in the development of woodworking machines have enabled Working Process, owner of the CML and WP brands, to get to know the needs of the window and door market, devising innovative solutions to simplify processes and reduce operating costs. The sum total of the skills acquired by this company located in Niviano di Rivergaro, a few kilometres from Piacenza, lies in the new line for the production of window and door frames developed for a well-known leading French brand. The solution, which runs for a total length of about 120 metres, has been conceived with the aim of improving the level of automation, reducing downtime and allowing the use of unskilled labour: from a simple rod of raw wood about 6 metres long, the machine is in fact able to obtain five completely finished pieces – i.e. turned, milled, drilled, squared, internally and externally profiled and machined in its details – in about 60 seconds. “Our mission is to improve the level of flexibility in a production sector that has always been rather rigid,” explains Fillippo Schegginetti, the company’s marketing manager. “Today, thanks to the collaboration of a partner such as Omron, we are able to carry out several machining operations with a single line; in practice, from the raw element we are able to produce a finished product that only needs to be assembled and sent for painting.

More than 200 controlled axes, in total safety

The new CML-branded window frame line, developed by Working Process, is based on a series of specialised stations for individual machining operations (multi-sided turning, drilling, milling, profiling), linked together by a series of automation components, including inverters and Omron servo drives (V1000, J1000, A1000). “This line,” explains Fillippo Schegginetti, “is the perfect combination of the skills acquired in the field of flexible CNC-based solutions and those more typical of the world of high-capacity lines. It is a very large line that exploits the high degree of freedom and flexibility”.

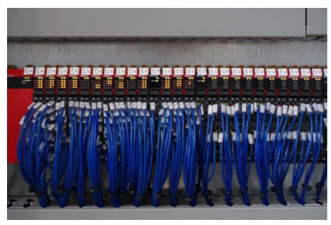

To govern the complexity – in total there are more than 200 controlled axes – Working Process opted for a central Machine Controller (Omron NJ) and an NX-SL safety controller (3500) to manage the guards, the power bias lines, all safety torque-off and EDM verification circuits. A dual-channel, cross-check verifies that the safety devices are in operation and assesses their activation and deactivation status.

The occurrence of any anomaly promptly triggers the securing of the area and facilitates the operator’s intervention for maintenance and restoration operations. Working Process also offered the end customer the possibility of interacting with certain parts of the line even while it is being worked on, thus guaranteeing the continuity of operations even during maintenance. The supply lines were

For this reason, the supply lines have been doubled, so as to enable the management of the tool magazine independently of production and to allow the operator to intervene in a protected area: “The motors,” points out Andrea Gardella, the company’s Automation Engineer, “are deactivated the moment the access door is opened.

More flexibility at all stages of development

The Sysmac development environment allows the advantages of an entirely PLC-based logic to be exploited, including safety. The development of the machine, from the concept to the complete line, has proved to be much more flexible than in the past: Working Process has been able to free itself from any conditioning linked to the electromechanical hardware, modifying the design choices originally made even during the course of the work, without any impact in terms of time or costs. Compared to the choice of using dedicated safety modules, the presence of a safety PLC in the programming phase also guaranteed a greater level of freedom, especially in the management of timings and identification of machine access areas.

The integration of third-party solutions also proved easier than any electromechanical solution. Through Sysmac Studio, it was possible to insert nodes into EtherCAT by remoting the safety inputs and outputs. “Having a safety PLC in the programming phase gives us a lot of flexibility,” Gardella emphasises, “because it allows us to modify the logic at any stage of development; even during testing, in other words, we can prototype our solutions. On plants of this size, such a distributed logic has many advantages, especially with regard to completion times’. Working Process obviously evaluated all the critical aspects related to possible interactions between man and machine. “We have tried to define a demarcation line, what the operator can do and what he cannot do to interact with the machine, how to guarantee his safety, both in terms of prevention and in terms of control and training. Every time there is an interaction we have a possible contact between the operator and a moving organ, therefore a potentially dangerous situation. This is why we chose to use an Omron PLC for all centralised safety management.

Diagnosis is timely

Despite a large number of stations, the line offers fully integrated management of activities, with all that this implies in terms of diagnostics. The logic allows the status of all components (including guards, interlocks, power contactors) to be displayed on a remote terminal and their status to be known in real time. Whenever an interaction with the machine occurs, such as the opening of a guard, it is easier for the operator to analyse the events. Working Process has drastically reduced the number of devices on each control cabinet, but above all it has enabled the end customer to reduce intervention times, avoiding the need to call in specialised technicians to analyse the cabinet’s circuit diagram.

The consultancy contribution of Omron’s Safety Service has allowed a correct approach in the application of the design guidelines with reference to the current legislation on machine safety, aimed at the realisation of the correct solutions to be applied for the achievement of safety for all the people working on the machine; this is also thanks to the professionalism and preparation of the people working within Omron’s Safety Service. “Working on a line of this calibre prompted us to study an effective solution with intrinsic safety,” concludes Fillippo Schegginetti. “Whereas in the past, the safety study was carried out after the plant design, we can now say that the two aspects go hand in hand. Starting off on the right foot with a partner who knows the opportunities and problems of each new project is the key to avoiding all those costly solutions that companies like ours often have to face later.”