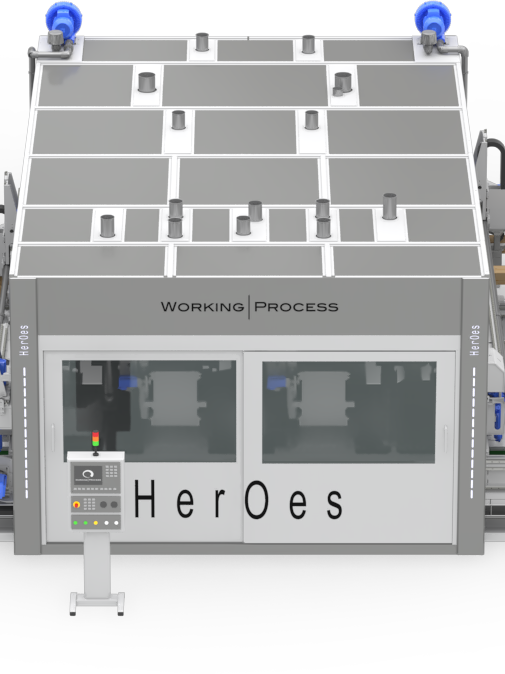

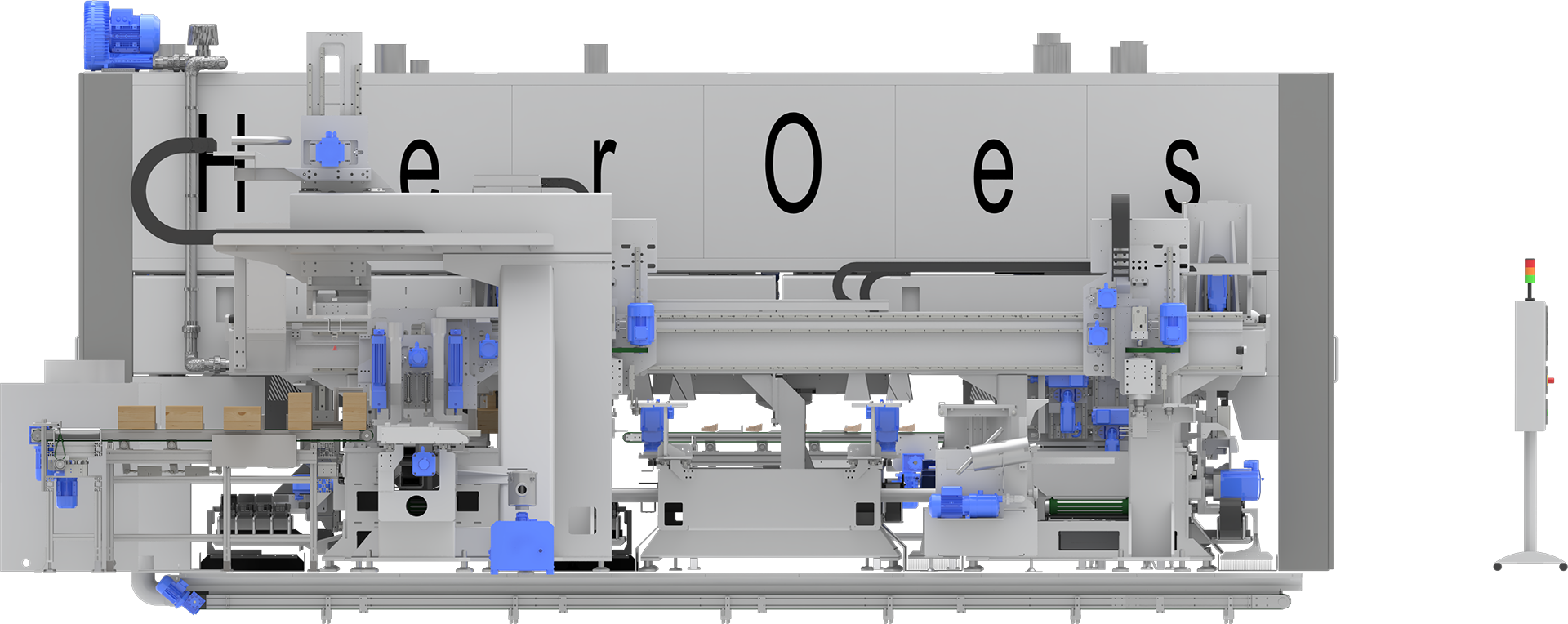

Heroes

The future of wooden frame processing is Heroes!

The best-in-class machine from Working Process, HEROES, is the result of a technological collaboration between Working Process and CML. It is a high-performance machining center for doors and windows, capable of producing up to 5 elements per minute. The clamping system, with 4 independent working lines, allows for flexible, high-capacity production, enabling access to all 6 sides of the piece during the work cycle. The use of additional special units allows for adaptation to specific performance and processing requirements. It can be integrated with the ‘Working Process’ branded smart loading and unloading warehouses, as well as with third-party machines such as saws/optimizers, moulders, sanders, and flow coating machines.

Ideal for producing 65 or more windows per day!

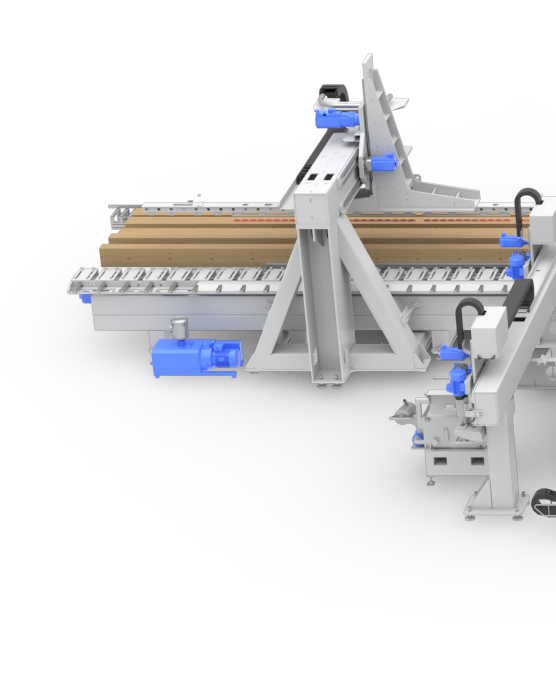

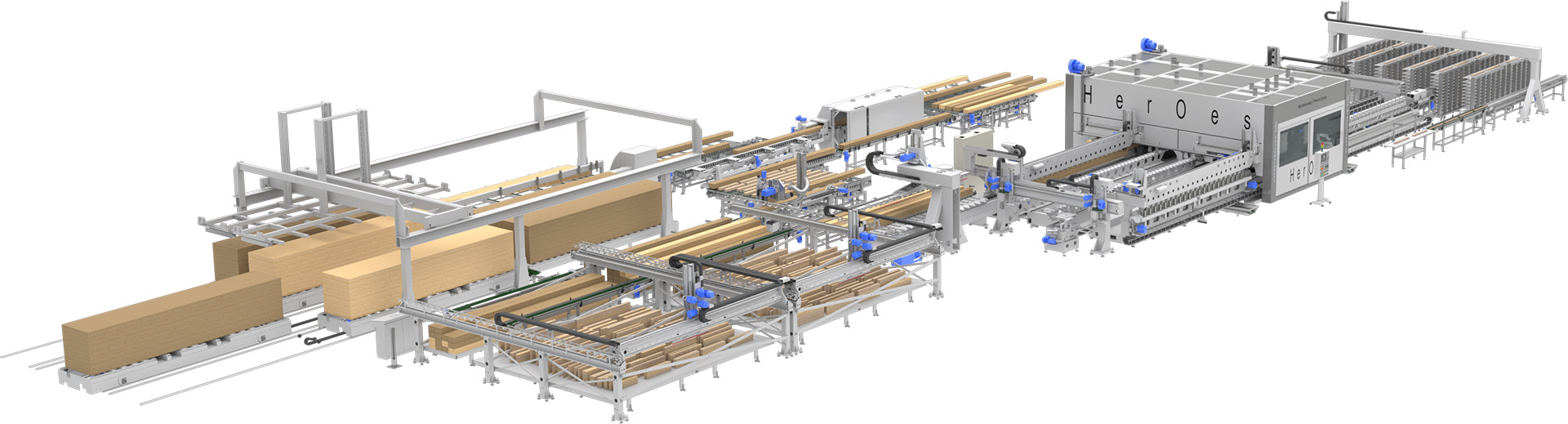

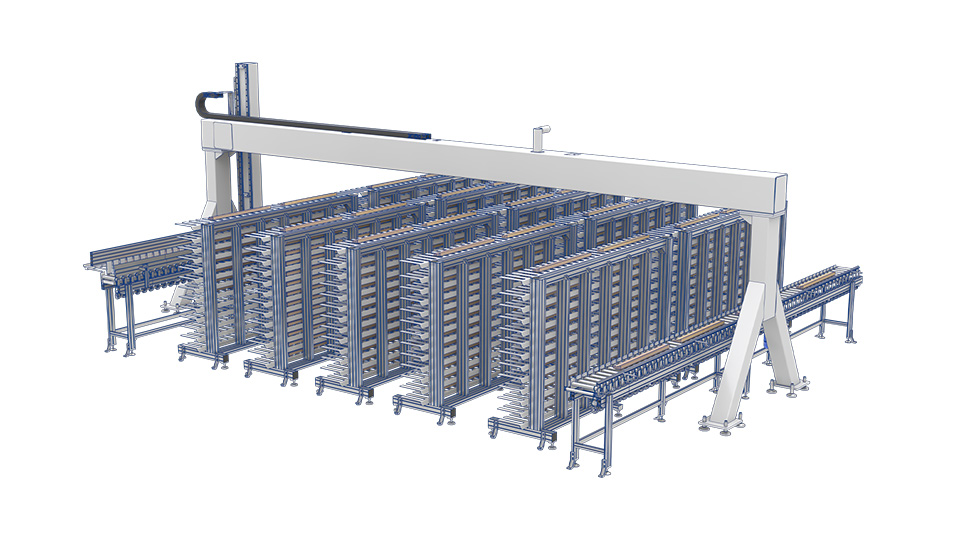

Loading System

The BB and IMML loading system is optimized for loading rows of pieces, maximizing available space, and enabling variable positioning of the pieces.

This fully automated system can load between 1 to 10 pieces simultaneously, ensuring their optimal clamping in the grips and enabling machining on all 6 faces. Additionally, it offers dimensional verification of incoming elements, optimization of piece arrangement in rows, load preparation, and management of pieces with different widths.

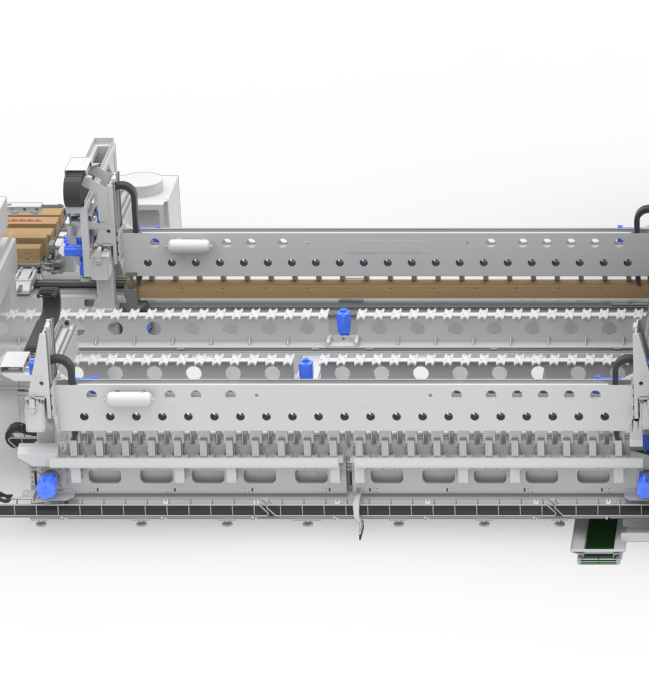

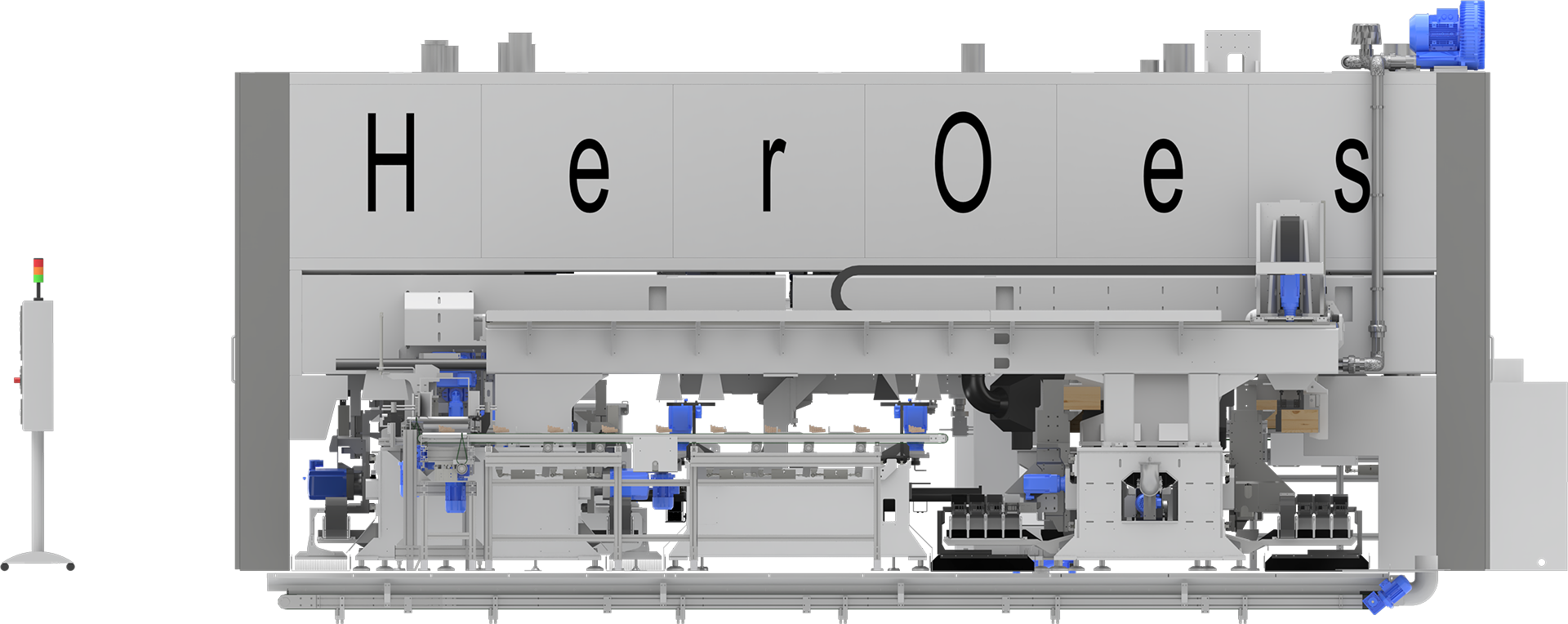

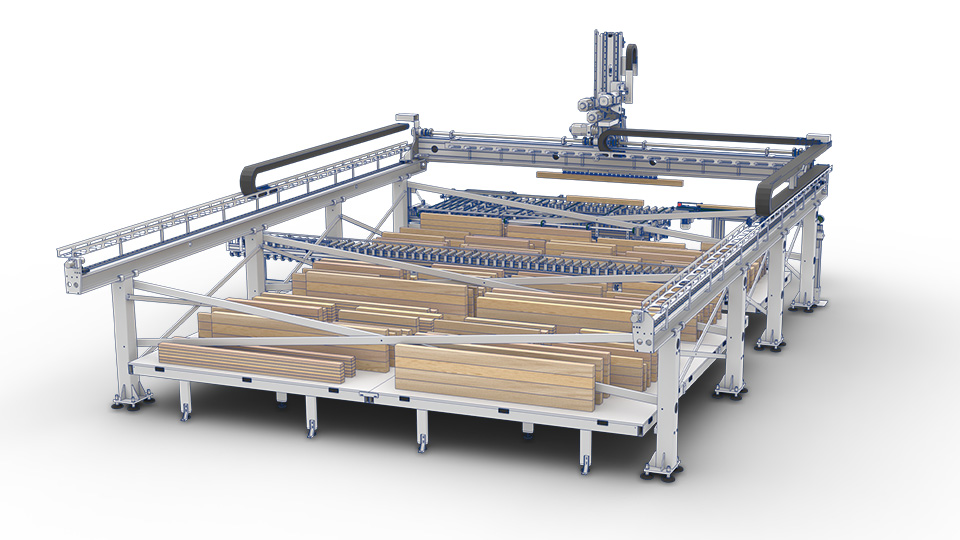

Transport Clamps

The double workpiece clamping clamps are designed with pneumatic closure and independent motorized longitudinal translation. Their size and shape have been optimized to ensure the best accessibility of tools to the workpiece during processing.

These clamps are managed as independent interpolation axes, offering additional flexibility that results in increased overall production capacity. The clamps are characterized by flexibility, robustness, and adaptability, with pressure adjustment according to specific processing needs and optimal positioning on the wood to ensure an effective and high-quality grip.

Each clamp is designed to be independent, with the ability to adjust the gripping pressure, reposition infinitely without compromising precision. Additionally, they are equipped with adaptable features, such as micro-needles, to handle different work phases and anticipate future processes.

Operating Heads

The T1, T5, and TBR operating heads represent the result of 20 years of research and development. For example, the double lateral clamping systems of the T5 heads, even with integrated C-axis, offer flexibility and precision in tool positioning.

This ensures optimal cutting conditions, reducing stress on the electrospindle.

Tool Magazine

The Tool Magazine is designed as a rack system with an electro-welded steel structure and with longitudinal sliding movement on guides with ball-bearing carriages.

The system allows simultaneous tool change operations on all spindles, reducing idle times and consequently increasing productivity.

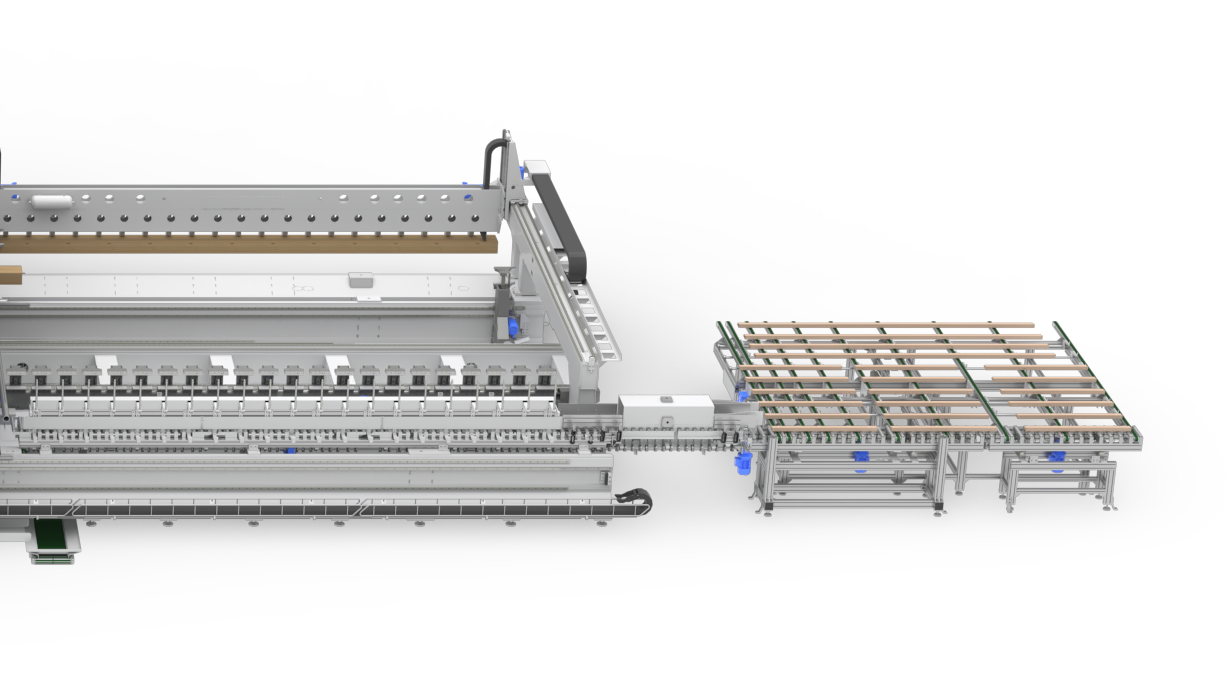

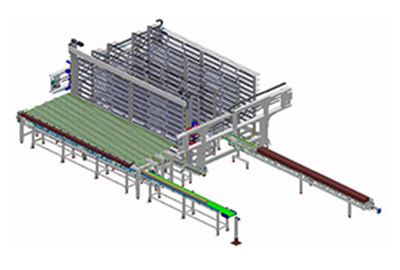

Unloading System

The proposed unloading system is highly customizable and modular, designed to ensure optimal efficiency in logistics management. Its ability to maintain a predefined work sequence ensures accurate synchronization during the unloading process, guaranteeing a seamless workflow and optimal resource utilization.

A key feature of this system is its extended operational autonomy, ranging from a minimum of 1 hour up to 3 continuous shifts (UML). This characteristic offers significant operational flexibility, minimizing downtime and allowing for continuous operations management.

The system efficiently performs unloading operations, including advanced quality controls to ensure compliance with standards. Additionally, it integrates an automatic labeling process at the end of unloading operations, simplifying material management and improving traceability.

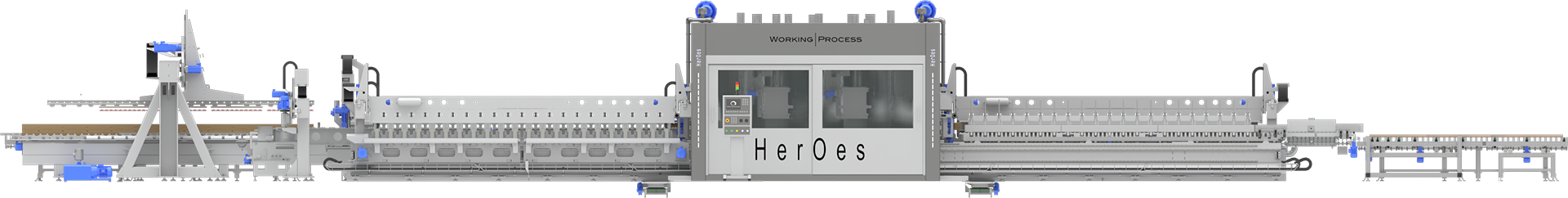

Heroes IMML Twin UML

Multi-spindle CNC window production line with manual workpiece loading and automatic unloading, 2 portals with 3 milling spindles, 10 fully independent workpiece-holding clamps and 160 tool places, ensuring maximum flexibility and productivity.

• 3 spindle motors T5/T5c/T5

• 10 indipendent clamps

• 160 tools rack

• Tool holder cleaning system

• 1 operator needed

• SB unloading

• IMML (optional)

• Space 17.4 mt x 7.5 mt

• 3 spindle motors T5/T5c/T5

• 10 indipendent clamps

• 160 tools rack

• Tool holder cleaning system

• 1 operator needed

• SB unloading

• IMML (optional)

• Space 17.4 mt x 7.5 mt

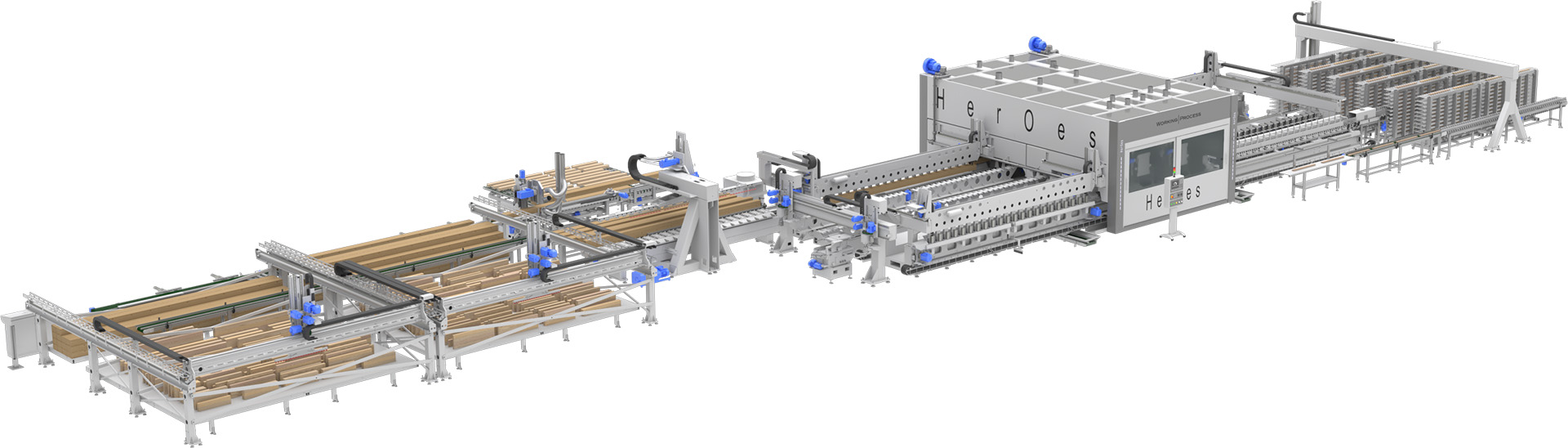

Heroes Full Concept

Multi-spindle CNC window production line with manual workpiece loading and automatic unloading, 2 portals with 3 milling spindles, 10 fully independent workpiece-holding clamps and 160 tool places, ensuring maximum flexibility and productivity.

• 3 spindle motors T5/T5c/T5

• 10 indipendent clamps

• 160 tools rack

• Tool holder cleaning system

• 1 operator needed

• SB unloading

• IMML (optional)

• Space 17.4 mt x 7.5 mt

• 3 spindle motors T5/T5c/T5

• 10 indipendent clamps

• 160 tools rack

• Tool holder cleaning system

• 1 operator needed

• SB unloading

• IMML (optional)

• Space 17.4 mt x 7.5 mt

Technical Specifications

HEROES

Operating System

SIEMENS 840D SL

Workpiece dimensions (raw material input)

Height: Min 20mm – Max 150mm

Width: Min 40mm – Max 300mm

Length: Min 230mm – Max 6300mm

Installed electrospindle power

S1 19Kw

S6 25Kw

C-axis positioning

360°

Tool holder

HSK- 63E

Maximum tool weight

15Kg

Maximum tool diameter

280mm

Maximum arbor length

260mm

Tool magazine

130/190 positions

Workpiece detection sensors

Height

Length

Width

Suction shutters

Number of shutters controlled depending on the model.