Just as the repercussions of the industrial revolution on the change in technological, economic and social structures that developed the production and transformation of material goods were analyzed at length, it seems difficult to understand what change the current digital revolution introduces in the very concept of design and to grasp the the connection between this sphere and a technology producer like Working Process is immediate; yet it is the companies that lead to the most ambitious projects – a reputation that is recognized after twenty years – that change the course of history. We speak with Paolo Perservati, the marketing director, about a company that has made mechatronics its flagship, giving shape to industry 4.0 for the production of solid wood windows and doors, ignoring the many obstacles also imposed on the vitality of the Italian productive fabric times of the coronavirus, to focus on an advantage that can instead be implemented, as Working Process is already equipped with all the tools, for example by regularly carrying out its main activities remotely, strengthening a whole series of attitudes specific to those who work in the digital age.

Let’s start immediately by explaining the concept of “advanced manufacturing” that Working Process has been able to develop and adapt to the specific sector of the production of solid wood windows and doors.

«Advanced manufacturing is synergistic with the new industry 4.0 model which passes through the concept of smart factory, in a Working Process composed of three parts. Smart production which is the integration of new production technologies. They create collaboration between all the elements present in production or collaboration between operator, machines and tools. The first benefit is immediately visible for the user, as it has harmonious flows of interaction between man and machine and between the machine and the company. The smart service, on the other hand, includes all the ‘IT infrastructures’ and digital technologies, which allow the systems to be integrated; but also all the structures that allow us, in a collaborative way, to integrate supplier – customer companies, thanks to the constant monitoring and connection of our operating machines around the world. We are always at the user’s side and can anticipate and prevent any long-term machine downtime.

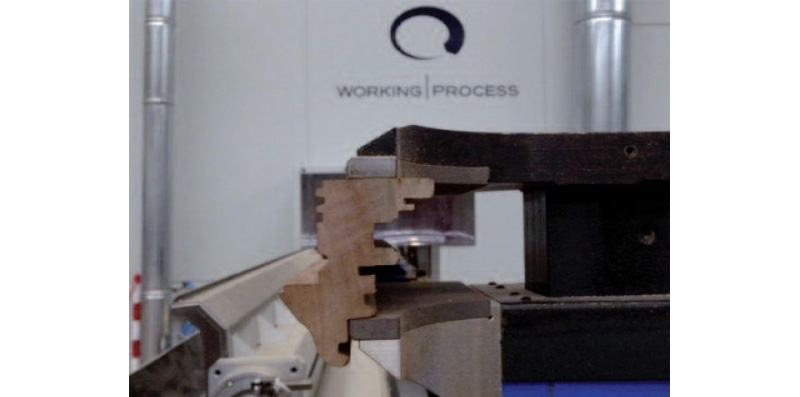

Knowing the status of the machine or production line is essential for all preventive service. Smart energy is attention to energy consumption, creating systems with better performance, reducing energy waste according to the typical paradigms of sustainability: the Working Process work centers use specific Siemens modules for the recovery of energy on the network, the consumption is very limited and the energy is sent only where it is needed. During tenoning and profiling operations, on systems even with more than 10 electrospindles, the use of the motors is optimized only according to the profile to be performed and the opening or closing of the suction ports is continuously controlled. We can say that it constitutes a revolutionary process of the very concept of manufacturing, in which knowledge-based manufacturing will become the basis of the new economy and new manufacturing. This is an important value chain that starts from research and development, design, through to engineering, marketing and logistics. In short, it is about giving value to manufacturing in a particular moment of evolution of Italian industry which we can define as epochal, as was the industrial revolution, inserted into the new industrial paradigm.

In fact, precisely in this model lies all the potential to respond to this particular moment given by the Covid-19 virus which effectively prevents companies from operating according to “traditional” logic.

What are the main parameters of this new “production” model?

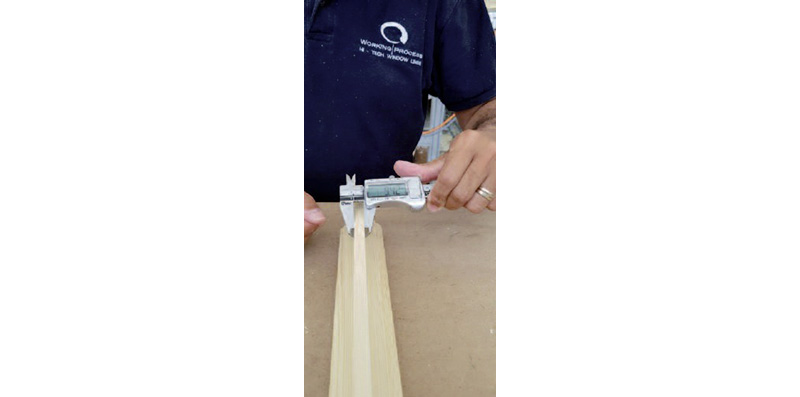

«Instrumental mechanics has evolved a lot in recent years to respond to user requests. The advent of high automation, the industry 4.0 paradigm and the continuous need for training of smart factory operators have imposed the need to design quality machines and systems. Today, price is generally not the most important parameter that buyers look at. The technological, energy saving and ease of use parameters are certainly the most interesting ones. For example, thanks to a user friendly interface, the operator displays machine data in a simple and intuitive way; touch screens for both the supervisor and the machine PLC are now widespread. Operators are trained to use CAD/CAM software even before the machine is mechanically ready; once the machine has been set up, training on its use begins. Furthermore, thanks to modern design systems, the development times for a new product have been reduced and the time to market has decreased. So in Working Process design and production are in harmony.” «We have decided, years ago – adds the Managing Director of Working Process Filippo Schegginetti – – to equip the production with portable workstations through which the technicians can directly access the drawings in order to view them, so they can see the element that they will have to create/assemble. Within ten months the entire company, and I mean every single department, will be equipped with a new management system to be totally interconnected, from production to marketing we will have a single database and obviously we will also have a latest generation PLM. The benefits will be multiple, you will be able to work better and there will be less chance of making errors or using outdated data.”

Is the latest generation mechanics such thanks to the advanced tools with which it is equipped?

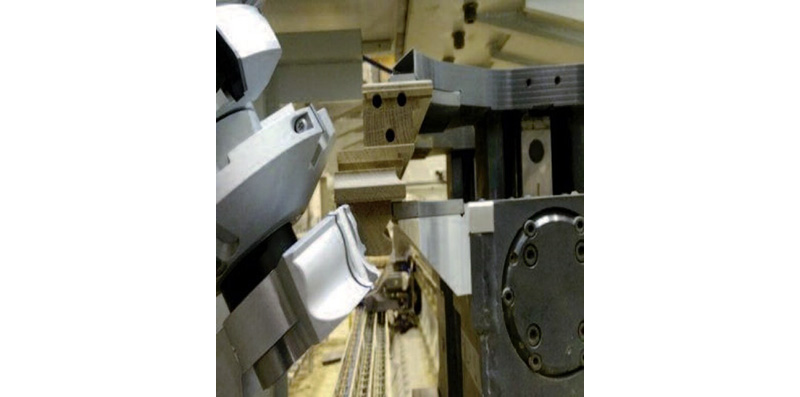

«Yes, in particular, it depends on the research, development and design systems and their interaction with the applied technologies. In Working Process the 3D CAD and Catia V5 design system is used which allows designers to perform FEM structural analyses. As regards interaction and human/machine interface systems, the company adopts latest generation technologies capable of making the use of the processing center or entire production lines simple. Even the loading and unloading of the machines is designed ergonomically in order to facilitate the operators. Furthermore, our systems include remote monitoring, both for preventive maintenance and for machine management. In the company’s technical office, Catia V5 is the main parametric 3D CAD design software created by Dassault Systèmes, equipped with a simple interface to use for any type of user. Consequently it is an adequate solution for the creation of complex machines and systems. It is able to cover the entire product development process: from conception to its creation and commissioning, in a fully integrated and associative way. Even in production and pre-assembly, the company uses Catia V5 workstations, which allow assembly workers to consult the 3D drawings of the machines and understand the assembly phases. Furthermore, all drawings are always updated with the latest revision from the technical office. A notable advantage since the various departments operate with the latest version of the project, avoiding errors or resuming work already carried out. By producing on order, acquiring the level of customization and added value that we give to our customers in a correct and up-to-date manner, from this perspective, always being up to the minute becomes essential.”

How does this hi-tech production process translate into the final development of the design product, a field in which today we also include the window?

«It is a hi-tech process, but easy to manage in Working Process because the development of an idea is shared with the user in a sort of co-engineering, we make our know-how and experience available and we apply them with the customer to carry out the project together. The ever-increasing innovation of production systems is not only linked to technological progress, but also to the presence of technicians capable of absorbing user requests and transforming them into concrete projects. To build a machine for making windows and doors you need to know the final product very well. All its current complexities, but also future developments, which is why we are always in close contact with market players: tool makers, software houses, systems engineers, manufacturers of hardware and other components that are now an integral part of the window. The study of the machine’s architecture is done following the rules of advanced mechanics and this allows us to develop truly accurate and refined products through advanced manufacturing.”

Quality and custom made of a design product, achievable with your technologies, which communicates with the universe of nanotechnologies and even subatomic particles – which physics is only recently discovering -, materials that reveal themselves from one day to the next under the electron microscope, influencing the creativity of designers, which is increasingly difficult to stem!

«Today in the world of woodworking, in all its aspects, the use of new materials which, combined with wood, create true works of art is of fundamental importance, a trend highlighted in recent years by the Salone del Mobile in Milan and Design Week, precursors to all other related events on the world market. So even modern woodworking machines must take many needs into account, to satisfy the tastes of producers and consequently consumers. It all starts with a good project: form follows function. Our design is aimed at optimizing the process and making it easier for the operator to work in the various phases of the production process. The construction of machinery and systems intended for the production sectors in the world of design is the heart of Made in Italy, without forgetting the food and fashion sectors. Our attention is focused above all on product quality and customization possibilities, two areas in which Italian creativity and know-how are unparalleled in the world. We are continuously focused on strategies to face a technological revolution that is by its nature constantly evolving and which cannot be renounced. Certainly research in the field of materials is in turn progressing thanks to the exploration capacity that the electron microscope allows today and this sphere will also involve wood”.

After twenty years, the Emilian company has established itself on the market precisely because of its constantly pioneering vision: what always puts you one step ahead?

«We do mechatronics – specifies Paolo Perservati – we design and develop both the mechanical part of our machinery and the IT, logic and supervision parts. We exploit global knowledge and creatively use the best in material technologies, software, electronic and mechanical components. This allows us to create cutting-edge made in Italy solutions for our partners and allows them to develop real competitive advantages over their competitors. In these twenty years we have put in place the strategies to face a technological revolution that cannot be renounced through the constant evolution of the “product, process, concept” scheme. We like to strictly deliver what we promise. But our work does not end with the delivery and testing of the system. The quality of processes is much more than the quality of products. We have created a virtuous system in project management that starts from the acquisition of the order up to the testing of the systems”.

Working Process’s production is centered on numerically controlled machines and lines for the processing of solid wood frames: has the strong specialization in this field become another distinctive sign today?

«When the company started its business in 2000, it had a well-defined mission: to revolutionize the methods of processing solid wood doors and windows by producing numerically controlled machines and lines exclusively for the processing of wooden frames. On a surface area of 30,000 m2, of which 10,000 are covered, we have been designing and building woodworking machines for twenty years. The company based in Niviano di Rivergaro, in the province of Piacenza, employs over 50 people and the reference markets are the main European countries but also those of production plants sold in other countries: from America to Australia. For the distribution of its products, Working Process avails itself of the support of local agents and resellers. We therefore do not set limits in our field and certainly the emergency we are experiencing will not stop us, even if it will have repercussions on the economy of every sector.

Despite the continuation of the emergency, the commercial, technical and production staff are fully operational, as are the suppliers. Like all companies, we are currently experiencing a difficult and uncertain moment, but in line with our DNA we want to continue to be proactive. We have adopted all the preventive measures and guidelines dictated by the WHO and we want to maintain the commitments undertaken with our customers with even more energy and responsibility. And in your free time you can fight the corona virus with a nice walk in the woods, because we at Working Process want to share with our contacts the passion and well-being that a material like wood, which we work with every day, is capable of transmit and “Forest Bathing” is truly an experience that we invite you to have.