The Mjøsa Tower will be the tallest building in the world to be made entirely of wood. 85.4 m high, it will have 18 floors above ground. Next comes the technological and structural focus.

Located approximately 107 km north of the Norwegian capital Oslo, the “Mjøsa Tower” is preparing to become the tallest building in the world made entirely of wood. 85.4 m high, the tower will have 18 floors above ground, thus exceeding the “Treet”, the current national holder of the title, by 36.4 m. The latter, as mentioned above, located in Norway and precisely in Bergen, boasts a total of 49 m of vertical development, but includes 14 floors. Currently still in the construction phase, the inauguration of “Mjøstårnet” is scheduled for March 2019.

Mjøsa Tower or Mjøstårnet: technological and structural aspects

Under construction in the town of Brumunddal, the “Mjøsa Tower” is destined to be the tallest wooden building on an international scale, narrowly beating the HoHo currently being completed in Vienna (84 m and 24 floors).

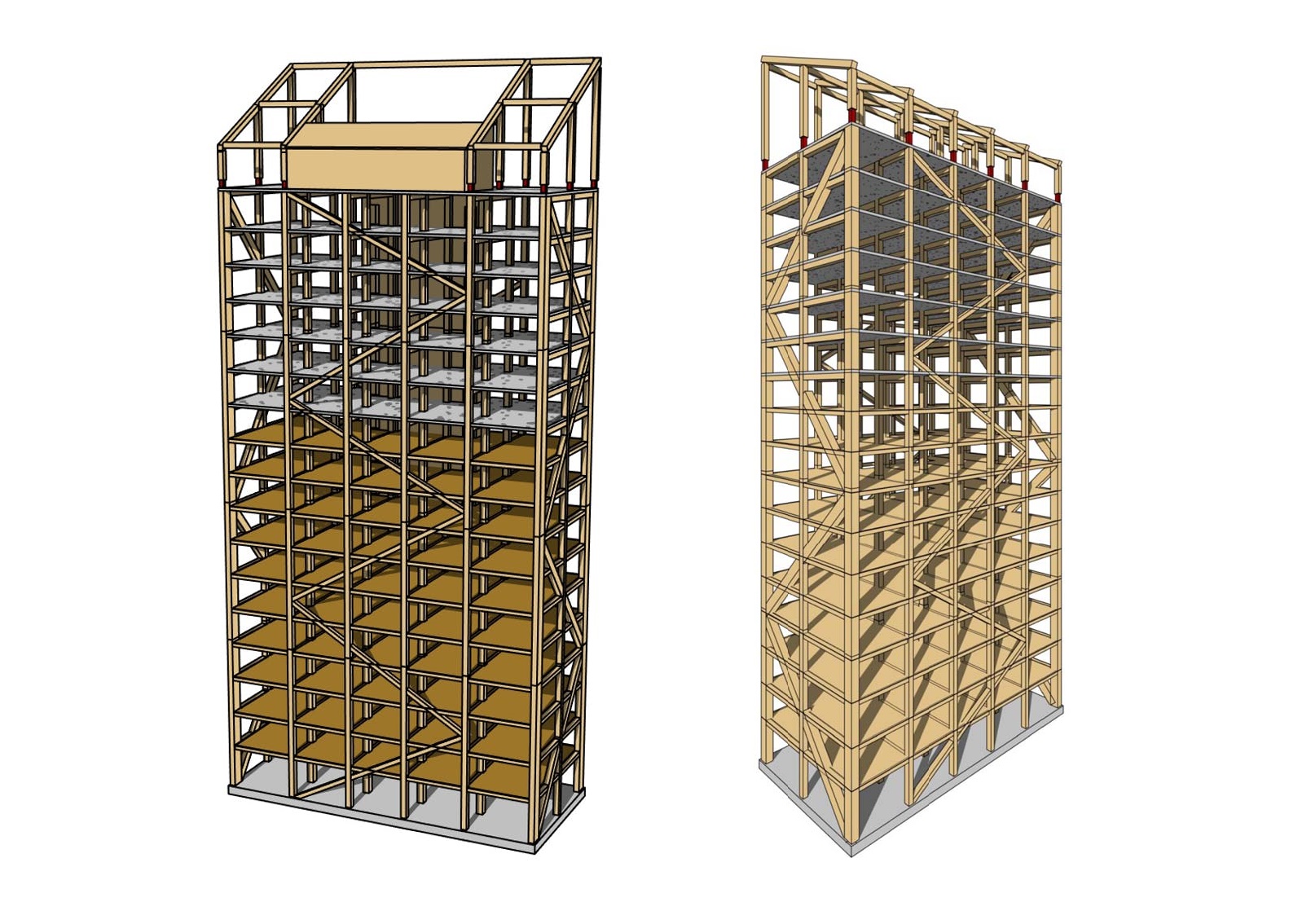

The main structure is of the frame type, therefore with columns, beams and diagonals in laminated wood. The cross section of the 4 corner columns is 1,485 x 625 mm2, while those typical of the internal counterparts are 725 x 810 mm2 and 625 x 630 mm2. As regards the beams, they have rectangular geometry, with dimensions of 395 x 585 mm2 and 395 x 675 mm2 for those supporting the wooden floors, while in similar ones supporting the concrete slabs there are increases of up to 625 x 585 mm2 and 625 x 720 mm2. Instead, the maximum size of the diagonal cross section measures 625 x 990 mm2.

The resistance classes of these “glulam” elements are GL30c and GL30h according to the EN 14080:2013 standard. CLT, on the other hand, is used to create the partitions of the lift and stairwells, to which slab elements made up of laminated wood beams and LVL decking (Trä8, from the supplier company Moelven) are attached. The value of its bending strength (fm,k) is equal to 24 MPa.

The Norwegian tower, however, prides itself on adopting a more purist approach to materials than the Austrian composite solution: it uses only 2,600 m3 of spruce, LVL and CLT laminated timber rather than combining wood (75%) with concrete. The hybrid solution, therefore obtained by combining one or more reinforced concrete cores with laminated or box-like CLT frame structures, was already used in other design solutions, such as in the Brock Commons in Vancouver. In reality, even the Scandinavian building appears not to be entirely made of wood, as will emerge in the following paragraphs.

The behavior and construction phases of the Norwegian skyscraper

In order to prevent oscillation due to the action of lateral loads attributable to the wind (speed of 22 m/s), the upper floors of the tower are in fact supported by cast concrete slabs (s=30 cm) with stabilizing functions. The concrete, in just the 7 top floors of the skyscraper, will make the oscillation slower and less perceptible to the tenants thanks to the contribution of its additional mass, however detectable in the order of 14 cm. Therefore, this material will have the function of increasing damping in the structures, as well as avoiding problems of motion sickness for its occupants. As is known, the oscillatory motion is guilty of the phenomena described above, due to the dynamic forms imparted to its actual structure; in the present case, it is equal to a height of 130-140 m, measured from the top of the building to the tip of the piles resting on the rocky substrate.

The timber used in the construction of the tower comes from the surrounding areas and is processed just 15 minutes’ drive from the construction site. The skyscraper was erected according to a total of 5 construction phases, each given by macro-portions of 4 floors in elevation; first of all, the laminated wood structure was assembled on the ground, on site, before being raised to the useful height and then installed. Similarly, the same modus operandi was followed for the horizontal plates, using powder-coated S355 steel plates and metal hardware.

The assembly of the elements in the construction of Mjøstårnet was managed without the use of external scaffolding, despite the complexity of the work carried out at height. To this end, cranes are mainly used, supported by hoists to meet specific needs. The gross surface area will be approximately 640 m2 for each of the 18 floors, with a footprint of 17 m wide and 37.5 m long in the Cartesian plane; these will house 35 apartments, 72 hotel rooms, offices and a restaurant, at a cost of around 450 million crowns.

Fire behavior and wooden buildings around the world

Finally, and regarding behavior in the event of fire, some notes. The prefabricated wooden panels present on the facade, of the sandwich type with interposed insulation, are protected from the free spread of flames with Firestop. The entire structural system is designed to withstand 120 minutes of contact with flames, while secondary elements, such as floors, must be able to withstand 90 minutes. Steel plates and plugs in the connections are embedded in the wood (≥ 85 mm). Furthermore, an automatic fire extinguishing system is integrated into the building and each room on the floor has been designed as a single cell, in order to limit the spread of a possible fire.

At present, according to the authoritative CTBUH (Council on Tall Building and Urban Habitat), there are 32 buildings with at least 7 floors in elevation that use CLT and/or laminated structural elements, on a global scale. The report, dated 2017, includes multi-storey complexes both completed and nearing completion, such as the Timber Tower by SOM, Dalston Lane by Waugh Thistleton Architects and the Tamedia Center by Shigeru Ban, already covered previously in the columns of ” engineers.info”. Among the project proposals, the French skyscraper “Baobab” stands out for its interest, 120 m high and 35 floors high, designed for the city of Paris by DVVD and Michael Green Architecture.