Article published in Xylon International February 2023

Fratelli Bozzarelli has two offices. One in Rivergaro is what we could define as the “classic carpentry”, although there is an important Working Process work centre. The second, in Podenzano, is the best example of the evolution that has affected the world of window and door production: stacks of semi-finished products ready to be “machined”, a large loading and unloading space, a work center that carries out every necessary process and a couple of people who – while the machine processes the pieces in orderly succession – can also dedicate themselves to other things.

A company born in 1975 – founded by Bruno, Franco and Mauro Bozzarelli – now in the hands of the second generation: Marco and the brothers Gianmario and Vera Bozzarelli. About fifteen employees with a turnover of around two million euros and the choice to invest in “high technologies” to open new paths, to work not only for the end customer, but also for other carpentry shops, for retailers to whom they supply the window ready to install.

“A year ago we decided to invest in a second Working Process machining center to turn our business around and broaden our market, thanks to a productivity that now reaches up to three hundred windows a month. To tell the truth, we were thinking of replacing the first Working Process machining center, which we purchased way back in 2007, with a new “Logos Life Exo Covid” convinced us to think big, creating a new production unit and updating our first Working Process”.

“The tax breaks have undoubtedly given an important boost to all the entities we work with – retailers, private individuals, construction companies – we have had rapidly growing requests,” adds Vera Bozzarelli. “We chose to invest in a complex moment, in the middle of the pandemic, when everything seemed destined to collapse. But we didn’t lose heart and went from thinking that perhaps the time had come to close down to the decision to invest a million euros in a centre!

“On the other hand, the world of carpentry has changed and those who have not invested in highly automated technologies have either decided to become resellers or only deal with installation,” continues Gianmario Bozzarelli. “Technologies that not only guarantee the necessary productivity and less manpower, but that can build the windows and doors that the market today wants, with increasingly reduced thicknesses to have the maximum quantity of light possible, obviously always guaranteeing maximum quality, tightness, of thermal and acoustic insulation. Today in our catalog we have wood-aluminium windows and doors, the possibility of providing certified solutions with thicknesses from 68 to 90 millimetres, lifting, tilting and any type of “oversize”. All processed in a simple and effective way thanks to the technologies we have chosen.”

Investing is the key…

“Undoubtedly: technology and organization are the key to success even for a small company like ours. A few months ago we acquired another warehouse, adjacent to the Rivergaro headquarters, which will allow us to have the necessary space not only to bring together our two production units, but also to equip ourselves with a new, very modern robot for window and door painting which already today we do but with equipment that is no longer in step with the times”.

But it must not have been easy for a “traditional” carpentry shop to choose such an innovative technology as the one proposed by Working Process…

“We have known Massimo Schiavetta (one of the founders and partner, ed.) since before Working Process was even born: we knew his skills, his vision and when he showed us what his machines could do, a world opened up. I was under twenty, but I understood that this would be our future.

Compared to the way in which windows were produced back then, we were on another planet, but it wasn’t easy to convince dads and uncles, even if when – in 2007 – the first Working Process arrived, an investment that was equal to our turnover of year, it didn’t take them long to change their minds…

I like to say that then the new Fratelli Bozzarelli was born, thanks to these work centers that give us an edge, which allow us to add value to the final product that our customer perceives immediately; machines that give us the availability in terms of working hours that is essential for us, without any problem.

With the new machining center we can work with “radius 2”, which for wood means getting very close to the sharp edge, but it is a characteristic that the market wants and that we can guarantee.

Without forgetting that, as I mentioned before, today we want windows with increasingly less invasive structures but which at the same time must “carry” increasingly larger and heavier glass surfaces, with thicknesses of up to 54 millimetres. Products that must have been designed and built in an excellent way, otherwise…”.

“In the space of about fifteen years we have transformed – Vera Bozzarelli tells us – demonstrating, in our small way, that any company can decide to change and face a reality that is always changing, which offers ever-changing challenges.

Now we are looking for new people to join our staff, more IT technicians than carpenters, and this is also a precise sign, although for us – in the end – the true value is the love for what you do, the passion… perhaps young people today have less desire to learn than previous generations, yet it is the only possibility to participate in the continuous evolution of the world and everything that surrounds us: this was what made us choose to work with the working centers of Working Process , to embrace their “philosophy”, to accept that in every aspect of our daily life everything is more electronic, digital, automatic”.

THE POINT OF VIEW OF “WORKING PROCESS”

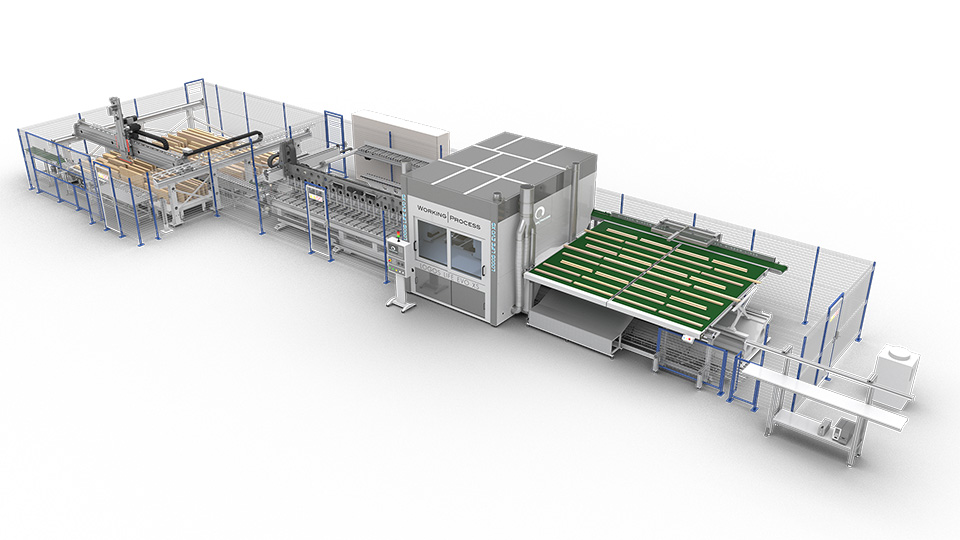

“A technology, the machining center in the production of doors and windows, which began in the early 2000s, when it was thought that just as happened for furniture, there could also be a “single machine” for doors and windows capable of bringing together all the processes carried out up to that point by different units”, intervenes Filippo Schegginetti of Working Process, who introduced us to Falegnameria Bozzarelli. “We were certainly among the very first, the first in Italy, to study, develop and propose this new technology which today has developed into very important plants, capable of very high productivity with a quantity of manpower estimated at a few people and, at the same time itself, in more compact machining centres, designed with smaller businesses in mind and with smaller production needs. From this thought the “Logos” family of machining centers was born, true highly automated systems that contain all our technology, all our ability to invent effective and revolutionary solutions”.

“The “Logos Life Evo ”, which can produce the pieces that the operator has loaded in complete autonomy, with lengths that can range from 110 to 6 thousand millimetres. Our independent automatic gripper system allows us to work with the same effectiveness and without “re-starting” extremely small as well as very long pieces. And we like to underline that on the same machine we can produce profiles for windows and doors but also the components of “inglesine” which can have a section slightly larger than those of a pen.

If once the machine represented the limit, currently it is the “form” that commands and the machine, the work center, has the task of carrying out the task received quickly and with maximum precision”.

A machine that you define as “compact”, but which is striking for the concentration of “invention” and technology that it demonstrates even just by looking at it…

“Our machines are all “important” creations in terms of technology and flexible response to customer needs. We are talking about solutions that have at least two operating heads – if we consider the “entry level” versions – with loading systems that manage the optimization of processes thanks to the independent grippers, ten in the machine installed at the Bozzarelli carpentry shop, which are organized in a automatically to bring the piece to work, regardless of its length, the interaction with the operating heads then begins, each of which can work with the necessary tools on the surface, to the side, under the surface of the wooden element: with our systems all six faces of the element are always reachable and available.

It is the result of long experience: we built our first units in 2006 and since then we have always invested heavily in ideas, in research, in the development of increasingly intelligent and useful solutions which have allowed us to guarantee unique results in terms of load of the operating heads, the effectiveness of the piece holding systems and the various necessary manipulations”.

… machines which, from what we understand, are less and less alone…

“Absolutely: alongside the actual work center we have defined automatic loading and tending systems thanks to which the entire pre- and post-machine cycle can be integrated. Our mission is and will increasingly be to provide complete solutions, from the raw wood warehouse to the unloading of the piece assembled in the order and ready for the subsequent phases, integrated lines, managed by our supervisory software, which can include our high-productivity cut-off machines “Cml” and soon also moulders that arise from our experience, built to our precise specifications and which we complete with the electrical and electronic parts. It is this set of experiences that allow us to adapt to the corporate organization with which we are called to collaborate to always obtain the best…”.

edited by Luca Rossetti