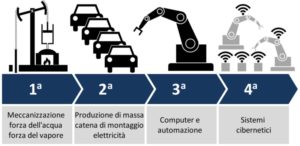

The Industry 4.0 plan allows you to create the intelligent factory, an opportunity to be seized to evolve and renew your company and be more competitive on the market of the future, i.e. the fourth industrial revolution. This is the thought expressed by Paolo Perservati, Sales & Marketing Director of Working Process.

«It may seem too early – he says – to announce that the fourth industrial revolution stimulated by the interconnection of digital technology has begun. But it is our customers who confirm this request. The growing and rapid pace of digitalization that is taking place confirms that the term revolution is not at all out of place. This is a radical change that is already affecting many companies and which, little by little, is spreading among those still left out.”

These technologies include advanced robotics and mechatronics, artificial intelligence, sophisticated sensors, cloud computing, data acquisition and analysis, digital manufacturing, software. Tablets, smartphones and other mobile devices, algorithms capable of managing and governing production plants and extracting data from them to increase the global value chain.

«Before Industry 4.0 – continues Perservati – these technologies were often thought of separately. Their integration and making them operational together allows you to further enhance and organize global operations by bringing the speed and functionality of the software and related data generated within the entire automated and interconnected production process. With Industry 4.0 we are able to give more value to our machines.”

Working Process has also long dedicated a lot of attention to the process of collecting and analyzing large quantities of data of different types.

«With the evolution of WWLine Supervisor – notes the Sales & Marketing Director, Paolo Perservati – we face the continuous transformation of the techniques and methodologies used. Internet of Things and Big Data are the basis of the efficiency and intelligence of a plant and the related production process. They have now entered companies in the manufacturing sector, becoming the paradigm underlying the fourth industrial revolution.

It is about applying innovative and digital technologies in the industrial sector that allow, through sensors and detection systems installed along the manufacturing process, on the machines, on the production assets, to collect a large amount of data and process it in real time.”

The real-time analysis of the large amount of data collected by sensors therefore remains fundamental and successful: this is the activity that supports and allows companies to make decisions.

«A significant change already underway – adds Perservati – which will continue in the coming years, and will give rise to a transformation of production processes, of the creation of value in technical assistance and repair processes, of engineering and product development processes».

The digital transformation process in which companies are involved to be competitive and protagonists is not just a technological question but a question of skills.

«Automated and interconnected production, with the introduction of new technologies – states Paolo Perservati, Sales & Marketing Director of Working Process – changes the ways of producing. But it also changes ways of thinking and corporate organization. Before being a technological revolution, what we must carry out is a cultural revolution. And, at the center of these evolutions, there are people. The resources who are called upon to operate the machinery, the employees who must manage and innovate the processes. The Industry 4.0 plan underlines as a strategic measure the importance of human capital which must be updated and in step with the new technological skills required”.

Even in Working Process, the updating, strengthening and adaptation of employees to retrain different professional skills and redesign working methods are the starting point for winning the game of the new industrial revolution.

«Continuous and constant training – concludes Perservati – to provide skills that go hand in hand with the changes of the intelligent factory. A transformation that must concern all company levels, from the entrepreneur to the employee, from the worker to the manager. Alongside digital skills, the ability to work with data, knowing how to read, analyze and classify it.”