We report for our readers the contents of a round table held in the Working Process plant in Rivergaro in the province of Piacenza, in one of the Silicon Valleys of Italian mechanical and mechatronics technology, with Stefano and Filippo Schegginetti representing the three owner families and with the company’s Operation Manager Paolo Perservati, the sales manager Italia Brevetti Stendalto Alessandro Merlino with the sales and marketing director Luciano Corbetta and Web and Magazine represented by Sonia Maritan and the publisher Pietro Ferrari who defined the meeting as a valuable exercise of teaching.

In the image from left to right: Pietro Ferrari, Stefano Schegginetti, Paolo Perservati and Filippo Schegginetti in the Working Process headquarters in Rivergaro in the province of Piacenza

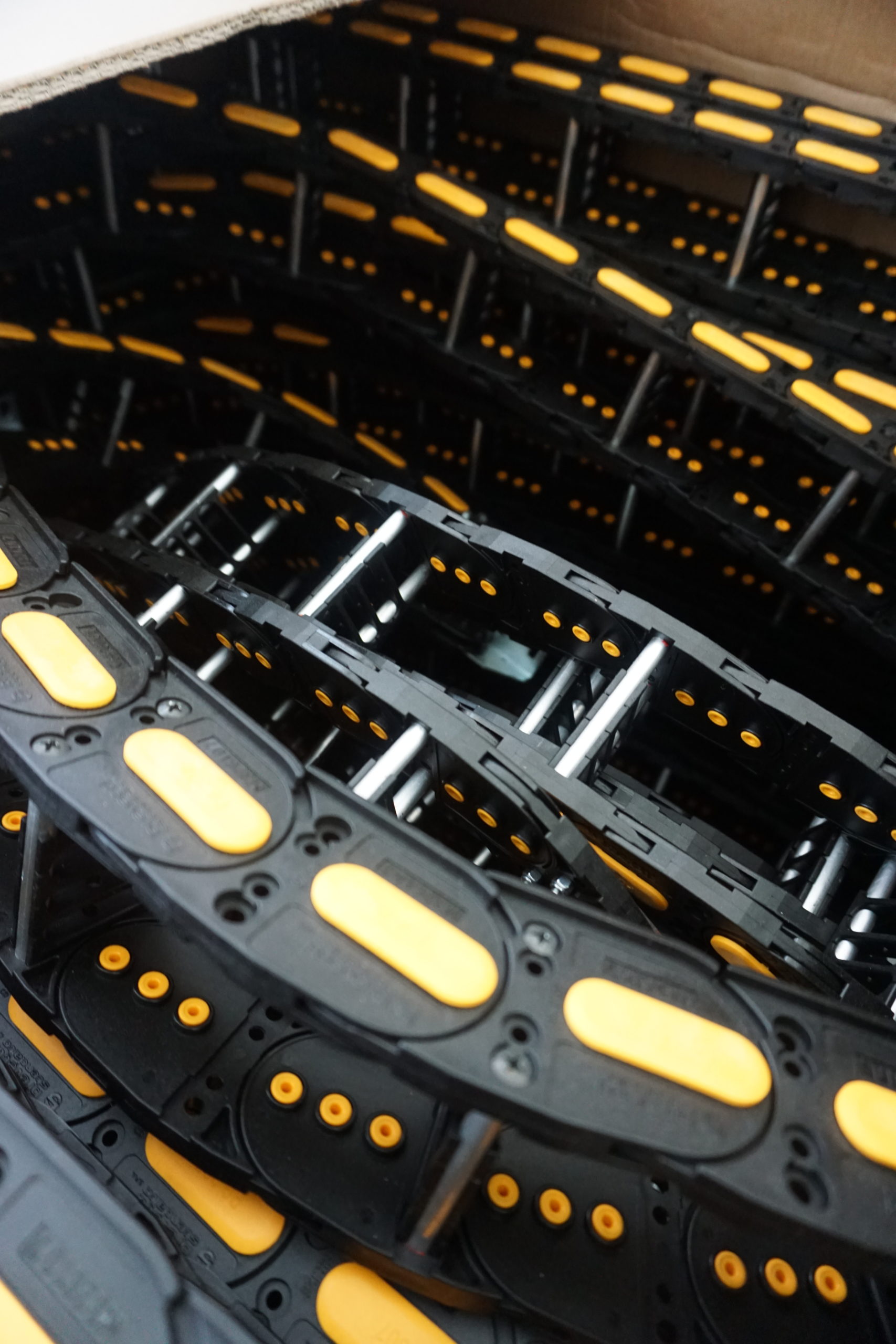

The Brevetti Stendalto cable chain.

From the conversation between the management of Working Process and the representatives of Brevetti Stendalto a reflection was born between authoritative partners on the creation of value, as Stefano Schegginetti defined it, but let’s start with the presentation of what is gradually represented as the boutique of the chain.

«Brevetti Stendalto is a 100% Italian company, made in Italy, I would say “made in Brianza”, born in 1968 from an intuition of Giovanni Mauri, still managing director and involved in the company in product research and development – he says Alessandro Merlino –, the story is typical of those years: it begins with the activity of a historic company from Monza, San Rocco, manufacturer of lathes. Steel chains were used on these lathes, because only those existed, but the idea soon was to have these chains molded in nylon to meet the emerging technical needs of lightness and translation speed.

The molding of these nylon chains was the work of a company, also from Monza, which made clotheslines, with the Stendalto brand (linked to its previous production) which remains today. The history of the Brevetti Stendalto company based in Monza began in 1976, where the semi-finished components made in the Mesero production unit were assembled, a reality active 24 hours a day on three shifts. Today, the second generation is present in the company, made up of Giovanni’s children, Claudio and Laura, who govern the joint-stock company in which the family is the majority.

The nylon chain was therefore born from Brevetti Stendalto and has spread throughout the world to the point that even today the made in Italy Stendalto chains arrive in the Chinese branch, preferred by the Asian giant’s top-level companies”. «We can add that the internationalization of Brevetti Stendalto began with the second generation of the family at the beginning of the 2000s – adds Luciano Corbetta – and that today, Brevetti Stendalto has six branches, in France, in Germany, in Norway, in United States, China and Australia. These are commercial branches which, however, in the United States and China, have the possibility of assembling the product, lesser possibilities of carrying out operations of this type also exist in the other branches. We think that today there are around 5500 product codes, which can be customized upon customer request.

So very often we start from the basic components and assemble the finished component.

Brevetti Stendalto is a very verticalized company: we ourselves are the producers of our basic components and we carry out the basic processing of the chains and the creation of the moulds”.

In the image from left to right: Stefano Schegginetti, Luciano Corbetta, Paolo Perservati, Alessandro Merlino and Filippo Schegginetti in the Working Process headquarters in Rivergaro in the province of Piacenza.

In Working Process the constant evolution of the “Product, Process, Concept” scheme involves the best specialists and influencers in the sector. Among these, in addition to window and door manufacturers from all over the world, a crucial role is played by supplier partners, as denoted by the start of the collaboration between Working Process and Brevetti Stendalto.

«Our collaboration with Brevetti Stendalto started in a challenging situation in which, as soon as we asked the sales manager to do something more to further improve the performance of the product used in Working Process – introduces Filippo Schegginetti –, we immediately received the visit of a technical manager as well as the sales representative who allowed us, with an appropriate upgrading, to bring our machines to a higher level.

So from a consultancy point of view it was not and is not just a relationship between a company that sells and a customer that buys, but we also move in the direction of finding solutions that go hand in hand with the evolution that we are experiencing.

This is fundamental, because finding a static and stagnant company on the other side, above all not capable of following and proposing alternative and innovative solutions to the problems that may be encountered daily, is disappointing, just as the exact opposite is important : the machine is standard as is the component even within its specialization and it is useful to talk about standardization when, however, highly customized products can also be made which within the production processes fall within standard production.

At the same time, the union of many standard elements that make up a tailor-made or sartorial whole, whatever you want, places the emphasis on something fundamental which is the analysis, from time to time, of a “unicum standard” ». «In fact, over time we have often found ourselves busy finding the right compromise between the standardized product and the one designed specifically for a single creation – confirms Alessandro Merlino –, following the speed of the Working Process step by step on different product ranges» .

We ask if collaborating with a technological leader in the wooden window and door sector has led them to also create specific chains that were not in the catalogue.

«We start from a base which is a standard chain but a device is added to the latter – explains Alessandro Merlino –, for example, against dust or shavings where there are high quantities of material removed, or we find very high speeds with very long chains that must be designed to withstand these characteristics.

This, for example, required frequent visits from our technical office and we must also underline the availability of the Working Process technicians to carry out tests with us”.

«Working Process has been building for some years with a philosophy that for us is a brand, so much so that TWC (Technology Without Compromise) is a registered trademark that represents a very precise, strategic, defined choice, desired by all the partners to go and build machines without any compromise – points out Paolo Perservati –, placing themselves in a high-end market not only in terms of price, but also of construction and the potential customer’s perception of being in a context that goes beyond the normal solutions.

Obviously, for us to be able to propose such an objective, suppliers must be an integral part of the idea.

Working Process probably could have chosen standard chains from another supplier with less performing solutions, but they would have had to accept compromises and this would not have been in accordance with our guideline and philosophy.

This is why our suppliers are increasingly an integral part of the company, they are strategic in design, commercial and construction choices, and this is certainly one of the reasons for the collaboration with Brevetti Stendalto.

In this case, if we want to go with certain speeds or certain lengths of the cable chain, we know who to turn to. It is therefore important that those who share this project have a similar philosophy.”

«What must be taken into consideration for the future is that this “value chain”, because that is what it is – Stefano Schegginetti intervenes – is made up of many margins: each company must have its own margin and must take advantage of the chain of the value itself. If some company is unable to maintain margins with adequate and competitive prices, it destroys the value chain, because I cannot sustainably purchase a component, no matter how excellent, at values that destroy my entry price into the market.

So the path we are following as manufacturers of machines that must have multiple components is to retain various suppliers who allow us to obtain a very high level product at the right price. The secret of the Italian victory over the rest of the world lies in the fact that the entrepreneurs of our country have understood that they themselves, depending on their specialization, must be able to commit themselves as much as possible to ensure that a small but fundamental component of machine or any other tool, gives rise, after having brought the right profit, to a finished product that is comparable in a correct and competitive manner within the market, otherwise we destroy the value chain. This value chain becomes a plus for our customer, a plus that allows him to produce at a high quality level with a fair market price in the technological investment.”

The tour of the Working Process production department in Rivergaro in the province of Piacenza, in the foreground, from left to right Filippo Schegginetti, Luciano Corbetta and Alessandro Merlino, in the background Paolo Perservati and Sonia Marita.

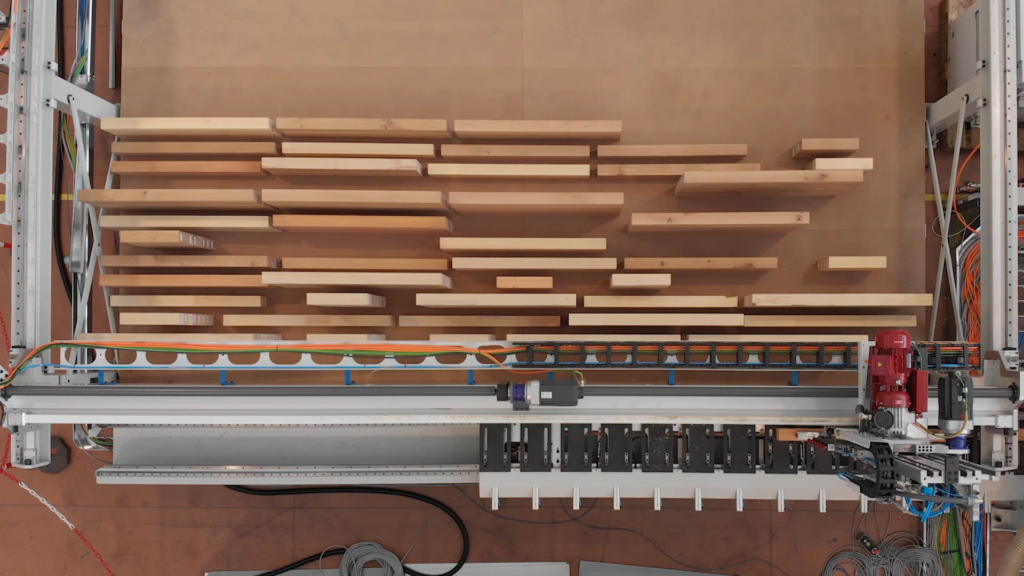

IN THE PRODUCTION DEPARTMENT ON 30 MARCH 2021 Filippo Schegginetti illustrates some systems in progress. The Logos Life Evo model, in this case served by intelligent warehouses both in the incoming and outgoing phase, is a system that currently mounts up to six in-line electrospindles as regards the EVO range. In the assembly phase for the Northern European market, in particular for the Benelux area, we have a Logos Life Evo . We are talking about a machine capable of being able to easily produce in flexibility with a maximum of fifteen-seventeen windows and doors, each different from the other, even with trapezoidal and arched shapes. It is a machine that, depending on its configuration, stands out in a market segment that Working Process initially looked at with interest but which today it is starting to tackle in an organic and organized way: we have therefore decided to focus on a machine that can be defined in quotation marks ” entry level” to guarantee what we consider the minimum necessary for the correct production of a quality wooden window, i.e. an advanced window which today can be considered a compendium of art which constitutes an element of design and prestige, generating an internal system, a habitat, a sort of “den”. What can be found in the higher series can also be found in this machining center – operating grippers, tool changer, manipulator and operating heads and Working Process structures – but with affordable configurations for a small-sized company, while being able to increase performance thanks to the addition of automation systems integrated into the machine, such as IMML/UML intelligent warehouses, parting, planing and handling systems, making the machining center suitable for flexible production and therefore always in a specialized field. It is a starting point for future implementations. For the Danish market, the assembly of the Heroes model serving warehouses is underway, in this case we are talking about an important machine, a work center that will completely manage the production of a large group that already has one of our centers of smaller size work. Alessandro Merlino shows some details of the cable chain. For each type of Working Process machine, Brevetti Stendalto creates an ad hoc code that generates a list according to the type of application. This is a job that is carried out both by the technical office and by our customer service from time to time. The codes are often similar but take into account every single variant, up to the most advanced solutions. Naturally there is always an effort to rationalize so as to be able to meet the most diverse needs with a limited number of models. Something simpler but also aesthetically more homogeneous.

We ask what the technological challenge was that Brevetti Stendalto faced with Working Process.

«The challenge was to find ourselves overnight having to rethink the relationship with the customer – replies Luciano Corbetta –, a customer who challenged everything that came before in terms of racing and speed».

«In practice it is as if the technical office of Brevetti Stendalto had moved to us – adds Filippo Schegginetti – to deal with a problem of this type». «We have gone beyond the customer-supplier relationship – underlines Luciano Corbetta –, in accordance with our current philosophy of presenting ourselves not as producers of cable chains but as suppliers of solutions».

«This is very appropriate – specifies Filippo Schegginetti – because the perspective has now changed drastically: the supplier-customer relationship is no longer the paradigm of ten years ago but not even of five years ago. Either we manage to follow a path of technical, mechanical or software partnership together or we cannot grow together.”

We are talking about an important partner because the cable chain is a fundamental component in the construction of a machine, but also in an infinite number of unimaginable applications, which in fact, like an umbilical cord, gives life to the movement of the machine and visually ‘edges’ the entire length of the line as an uninterrupted eminently technological ‘festoon’. In this sector, Brevetti Stendalto, to which an article will be dedicated in Industria del Mobile, is a point of reference in the sector.

«In our design evolution we are thinking of a path aimed at carrying out a greater number of pre-assemblies – continues Paolo Perservati –, which allows us to produce more quickly». «For us, working on orders is becoming a standard – specifies Luciano Corbetta – a product line like Total Chain».

«We want to have the first experience on an entry level machine that goes in this direction – explains Paolo Perservati -, the results of this exercise will be transferred to the other machines, so that we can significantly reduce construction times, but not only: we want to work not only on construction times but also on installation times, i.e. assembly and disassembly in the factory and assembly at the customer’s site which we still consider too long: to arrive not at plug&play but at a very compact time”.

«This path goes exactly in the direction we are taking – agrees Alessandro Merlino – also in tune with the evolution of customer needs».

«This – adds Filippo Schegginetti – would also lead to savings in hours of work and material». «In this way – adds Alessandro Merlino – the warehouse of cables for mobile installation would tend to zero for you».

«Obviously distinguishing between the high-level and highly customizable machines which are islands – specifies Filippo Schegginetti – and the machines of current production».

«Also considering that the purchasing office orders everything with a single code – specifies Alessandro Merlino –, also for this reason, if before no one bought the wired chains, today many are arriving»

«At the beginning of the year we started to create a sort of business unit to which we entrust the electrical diagrams and their design which were previously outsourced – highlights Paolo Perservati -, today we have two dedicated resources who deal only with these aspects: this allows us already to arrive in advance on the knowledge of the data we are talking about.

We are trying to bring all these activities in-house, we are preparing the undergrowth to move in the perspective we were talking about, to make an order standard, because an order must be special in terms of technology and production processes, but it must be standard for construction processes: this is obviously a concept that embraces the entire company where we don’t work in watertight compartments.”

The standardization of the production process recalls – considering the range of Web and Magazine magazines also dedicated to construction – the production, construction and construction process in the field of structural wood, conceived through the prefabrication of the elements. The difficult thing in this sector was to make it clear that it was not a debasement but an enrichment, because it meant working dry and reducing times and costs, without precluding the customization of the building. The result is that the end user can have the house assembled in a few days.

«A component that is studied on the drawing board – agrees Stefano Schegginetti – to then be sewn exactly in the field».

«A refined job done with constant checks – reiterates Alessandro Merlino –. This is why it is important for technicians to talk to each other, the relationship between companies is not just commercial, when the technicians find the right solution, the commercial relationship goes without saying.” «Of course – underlines Paolo Perservati –, the incubation must take place in a technical context».

The technical-performance factor is important! And the speed?

«The fundamental factors – replies Paolo Perservati – are the relationship between performance, understood as speed, containment capacity on the structure, load-bearing capacity or relaxation over a seven-metre stretch.

Not so much on speed, which is a relative concept, but on accelerations and decelerations…”. «I would add – says Alessandro Merlino – the pull and the push…».

«I would also add – continues Filippo Schegginetti – the durability of the product within constant work cycles». «We must consider that we have speeds understood as an acceleration ramp close to gravity – Paolo Perservati elaborates –, values that are very high: the speed in and of itself is made critical by very rapid accelerations and decelerations…».

«This is the main work of our technical office – explains Alessandro Merlino –. In the case of Working Process we are talking about medium-long runs, so other concepts come in which make the work more difficult but also more challenging.”

«We also consider – specifies Stefano Schegginetti – the environment in which the chain works».

«It’s like unwinding a ball of yarn in reverse: if I throw it one meter away the thread goes straight – explains Paolo Perservati –, but if I throw it twenty meters away it’s not so simple, you also need a guarantee on the flow».

This is why we are pushing more and more on the Total Chain – explains Alessandro Merlino -, because the chain is assembled and installed correctly in order to guarantee maximum cycle life”

And what about maintenance?

«Regarding maintenance – replies Luciano Corbetta to Sonia Maritan –, let’s say that the expectation of our customers is not to carry out maintenance».

«Also because the only sensible maintenance of the chain – confirms Stefano Schegginetti – is to replace it».

Speaking of disposal, is there a policy at Brevetti Stendalto on these issues?

«There is no institutionalized policy – replies Luciano Corbetta to Pietro Ferrari –, there is the big advantage that the material we use can be 100% recycled: nylon reinforced with glass fiber is essentially a polyamide and can enter totally in a regeneration cycle. Given the indirect structure of distribution, it becomes difficult to recover the material, this is a process that we would like to explore further with our customers, also because it involves recycling an expensive and valuable material, to enter into a circular economy process”.

To Sonia Maritan, the cable chains appear like umbilical cords of the machines and certainly when the system is moving they are clearly visible with the typical yellow color of Brevetti Stendalto.

«Cable chains are a limited cost element on the total cost of a machine like those of Working Process – concludes Alessandro Merlino –, but a machine downtime caused by the poor quality of a chain can cost a lot in terms of machine downtime for the customer and of image to the technology supplier”.

By Sonia Maritan

Web and Magazine