Article published in XYLON , May-June 2022

A company that, in just over twenty years, has earned itself a prominent place in the world of window production technologies, thanks to lines and machines highly appreciated by major European and global manufacturers.

We admit it: we don’t know where to start. The (ample) morning spent in Niviano di Rivergaro, just a few kilometers from Piacenza, was full of information, stunning views of the Piacenza countryside, stories, and a vision that once again impressed us. The last time we visited Working Process, a brand now celebrated worldwide for the window production work centers it offers, was in 2012 for the inauguration of the new headquarters that came as part of the acquisition of Cml-Centro macchine legno, another brand many will remember, and which today represents the Working Process division focused on large production lines, still dedicated to window production.

And we were truly impressed by what we saw, which we will try to summarize in these pages, starting with some figures: in twenty-two years of history (the company is one of the few “millennials,” founded in 2000 in Settima di Gossolengo), the mission has always been to build machines for producing doors and windows. Today, 70 employees work towards this goal, achieving a 2021 revenue of 21.7 million euros, a 22 percent increase over 2020, with 5 percent invested annually in research and development. The machines and lines stand out for their technological content, chosen by the upper-middle range of the market, as Working Process has decided to target both “important private companies” and large international groups planning investments that can reach several million euros, allowing them to produce up to ten units per minute, all “batch one”. Eighty-five percent of revenue is generated in Scandinavia, France, Germany, Austria, Belgium, Switzerland, and Poland. These “top-level” solutions are produced in a bright 10,000 square meter facility, near which another 3,000 square meter warehouse is already ready—an essential addition, as there is truly a lot going on.

To the point that we almost forgot the main purpose of our visit was to talk about sustainability, but luckily Filippo Schegginetti—partner and marketing manager of the company—reminded us: “Beyond the big issues, for us, sustainability is a word that must be filled with concrete actions, even small choices, which we pursue every day with commitment. We are a low-energy-consuming company, with a minimal impact on the territory. Wood chips are compacted into briquettes, which we give to our employees for their stoves. We have planted a fruit tree for each of our employees and for those we will hire. We are building a large photovoltaic system that will reduce our energy demand, a commitment we have also followed in the construction of our workspaces. Our lighting systems are energy-efficient, and we do what we can to support organizations and institutions that care about people’s well-being, as well as our employees and their families, for whom we have activated a series of initiatives.

On the other hand, to build machines as beautiful as ours, you need happy, satisfied people! People are important, their well-being is a priority, and we want to do everything possible to create a peaceful environment that fosters dialogue and helps build that essential “positive atmosphere” in the company, which we believe is one of the most important ingredients in the quality of our machines, into which the passion of all seventy people who work under this roof every day is poured.”

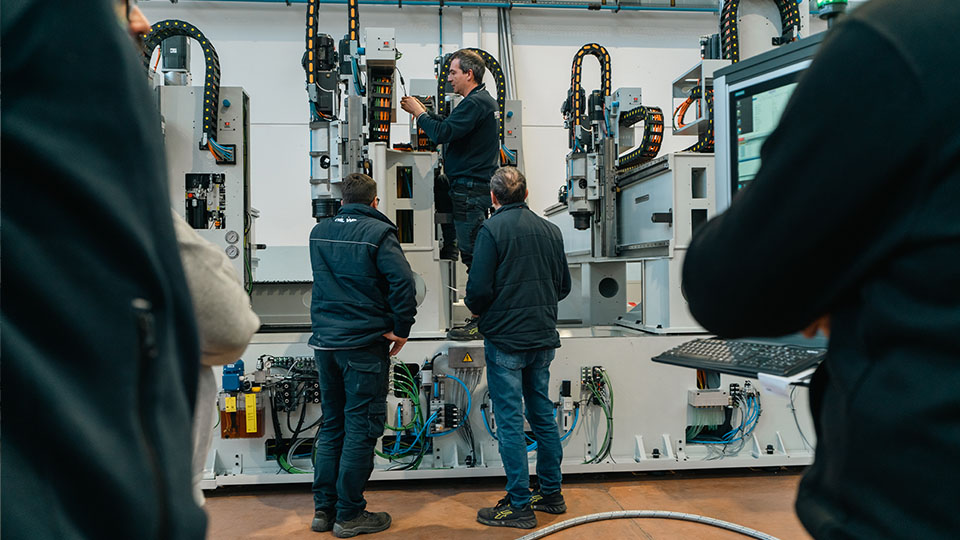

“And for us, sustainability also means encouraging collaboration and communication between people,” continues Filippo Schegginetti. “At Working Process, every machine, every system is discussed and shared, a fluid exchange that allows all of us to feel like we are part of every single machine that leaves our facilities: smooth operations, people communicating to contribute to the company’s project, which is the production of the most advanced technology available today for the window manufacturer of tomorrow. Yes, because for us, sustainability means above all providing our customers with machines and systems that not only meet current needs but also allow them to look to the future, to create new standards, better windows, and perhaps even more eco-sustainable ones.”

Let’s talk about machines: could you tell us what your strengths are?

“The perfect harmony with which all the vital components (clamps, manipulators, operating heads, tool storage) interact with each other, providing flexibility, versatility, and productivity, ensuring the best return on investment. We have always designed solutions oriented towards the entire ‘machine system,’ considering what comes before and after each work cycle. From there, we decided to focus on developing process automation systems that combine various production flows, from cutting to entering the painting phase, enhancing and respecting the potential and ‘nature’—if we can call it that—of each work phase and the machines involved. In 2005, we developed a production methodology we called ‘the three Ps of the production process,’ where each ‘P’ symbolized a specific advantage for the customer. To date, this methodology has evolved to include ‘seven Ps.’ It’s worth noting that as early as 2010, we tested the prototype of our ‘IMML’ (intelligent multy-level magazine), an innovative intelligent storage system that allows for optimal management of the different dynamics that cutting, planing, sanding, and the work center respond to, creating an intelligent and effective cycle. To date, we have installed over seventy of these, achieving excellent results in optimizing the different processing stages, individual machines, and order management. This is just one example, but solutions like these allow us to say that while we used to have to sell our machines, now they are chosen because window manufacturers recognize our expertise. They know we are ‘window makers at heart,’” Massimo Schiavetta tells us with a laugh, “and we speak the same language.”

“We chose to be highly specialized, to occupy a niche within an already niche sector. We wanted to do it as leaders. We wanted to be the best. Our strength lies in the ability to analyze, interpret, and manage the entire process from ‘A’ to ‘Z,’ even in a fully automated way if that’s what the customer needs. This expertise is recognized not only in our technologies but also in the level of service we offer to meet all the project’s goals. We are aware that when a company chooses us, they are entrusting us not only with an order but also with their past, present, and future. This requires great seriousness, respect, and the desire to win together.”

“These are relationships that become very close, collaborations that rarely end, partnerships that last for years and help both us and our clients grow, with whom we have a continuous support relationship. Thanks to new technologies that provide significant data, we are always by their side to offer advice, to share any questions, and to make new decisions that take all the elements into account and continuously improve performance.”

Beyond the normal supplier-customer relationship…

“We have always believed in the wooden window and door production sector, and we have always continued to invest and work intensively—even during the difficult years of the crisis, we did so with even greater conviction. We started by becoming promoters of a new window system. First, we thought of the ideal product that our client could sell and profitably produce, and only then did we consider the new type of machine we could offer them. A machine that had to go beyond the technological limits present in the market at the time. We involved, refined, and invested energy into our collaborations with toolmakers, software houses, and the key players involved in the window development chain, collectively imagining new technologies that could do everything other machines could not—different machines, so we could be the first to move in new directions, always striving to walk the path the market had chosen with our clients, and if possible, to lead it.”

“It hasn’t always been easy, because our machines have an enormous amount of detail, which is our responsibility to help our partners appreciate, to make them passionate about the choices we have made so that they can turn those choices into an absolute advantage for themselves. You see, we have always tried to answer what we call the ‘five big questions’.”

“First, the product, a catalog of solutions that allows our client to meet their goals and profit with an offering that stands out from competitors. Then, the production process, which must be designed to maximize results. At this point comes the machine, the technology, which is the best possible answer to the first two questions. Then comes the technology partner, an ideal figure—someone full of values, determined, and competent in every aspect of the project.”

“Finally, the customer, a key player for success. Contributing to improving their knowledge helps secure another positive reference. In short, we acted to create a reference market to which we could direct ourselves.”

“Working Process asked itself these questions and provided its answers: today we are an absolute reference point in window technology, and those who come to us know exactly what they will find.”

“We are now reaping the benefits of decisions made many years ago, knowing we can and want to offer something more and something better—not just selling a machine, but positioning ourselves as travel companions, someone they can rely on even for more general strategic choices.”

“We can do this thanks to our knowledge of the sector and our experience, which convinces clients to involve us in their decisions, fueling our insatiable hunger for work and innovation. After all, we are the youngest company operating in this world, and coming last imposes two things: you have to be different from the others, and you have to demonstrate a love for the customer that the others have not shown.”

Let us return to the initial topic, sustainability: we’re talking about an innovative window also from this point of view…

“… and one that can be built with our technologies.”

“This journey began several years ago and is now complete: we are talking about a wood-wood window, where—in short—the function previously assigned to the external aluminum profile is now performed by a similar wooden frame, which can easily be replaced, although it is made of particularly resistant wood species. Of course, both the window and this new profile are made using our technologies, and I believe it’s clear what it means to offer an ‘all-wood’ window that comes from our technical response to the issue of wood durability and maintenance.”

“This is a new development we have worked on because we saw it as an opportunity consistent with our way of acting, thinking, and offering: a window that is even more eco-friendly than existing ones, providing the end consumer with a product that is even greener than current options.”

“This innovation also reflects our way of being, our constant desire to tackle every challenge as a large company, thinking big and committing to achieving what is necessary to maintain this mindset.”

“I would like to add that we have made this company sustainable not only in environmental terms but also in ethical and social terms,” concludes Filippo Schegginetti. “We engage in transparent dialogue with all our stakeholders, paying attention to every detail that allows us to consume less, even installing energy recovery systems on our motors. We put all our efforts not only into building excellent machines but into doing so with the mindset that every action we take must have the lightest possible impact on the planet.”

“We look to the future with confidence, certain of our foundations and with the determination, alongside everyone who is part of the ‘Working Process world,’ to go even further.”

Edited by Luca Rossetti

Article published in XYLON , May-June 2022