ALL-IN-ONE TECHNOLOGY

A single machine for your wooden window production

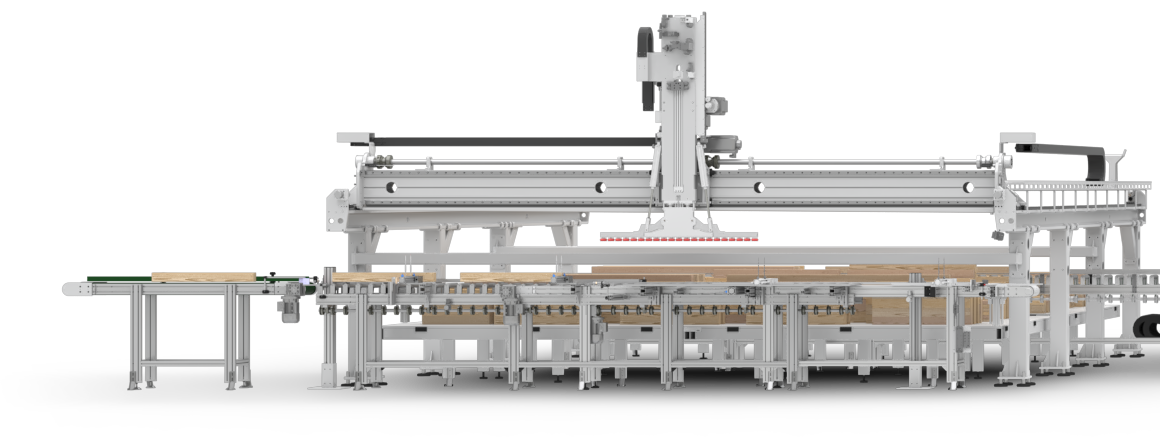

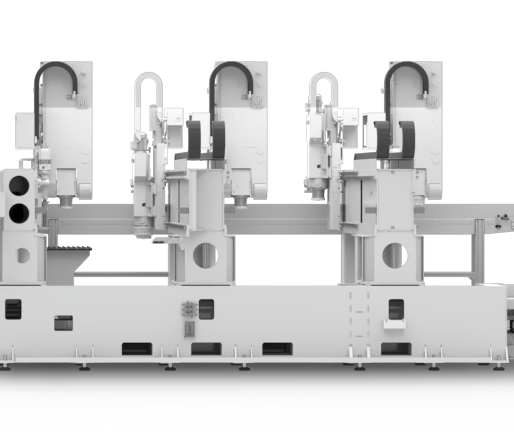

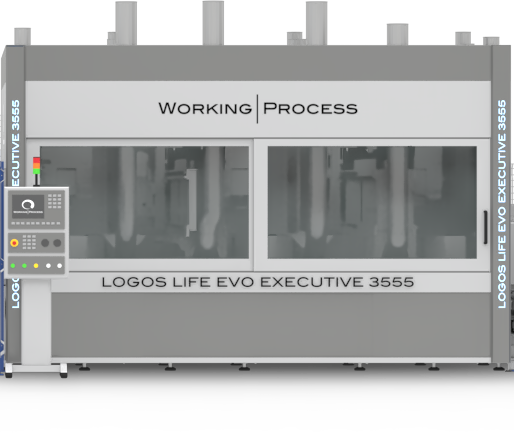

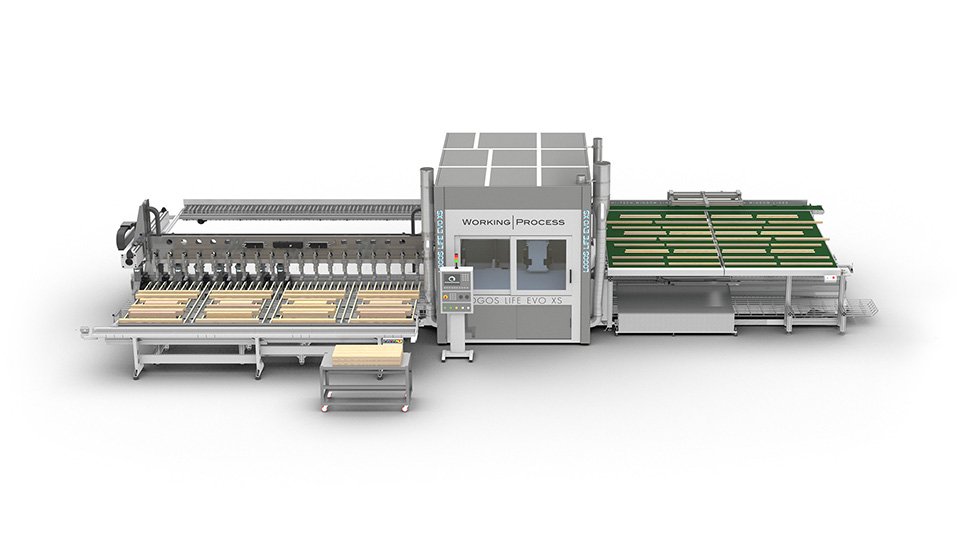

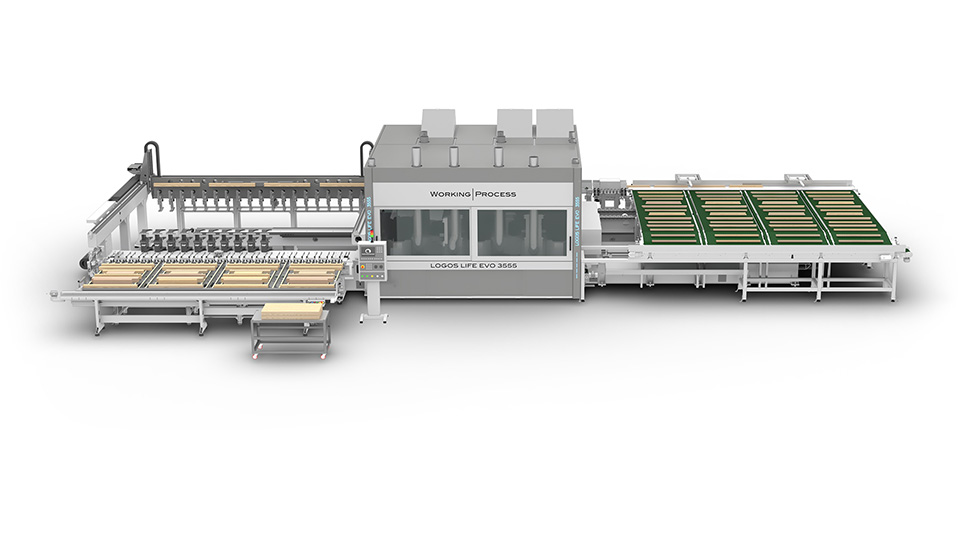

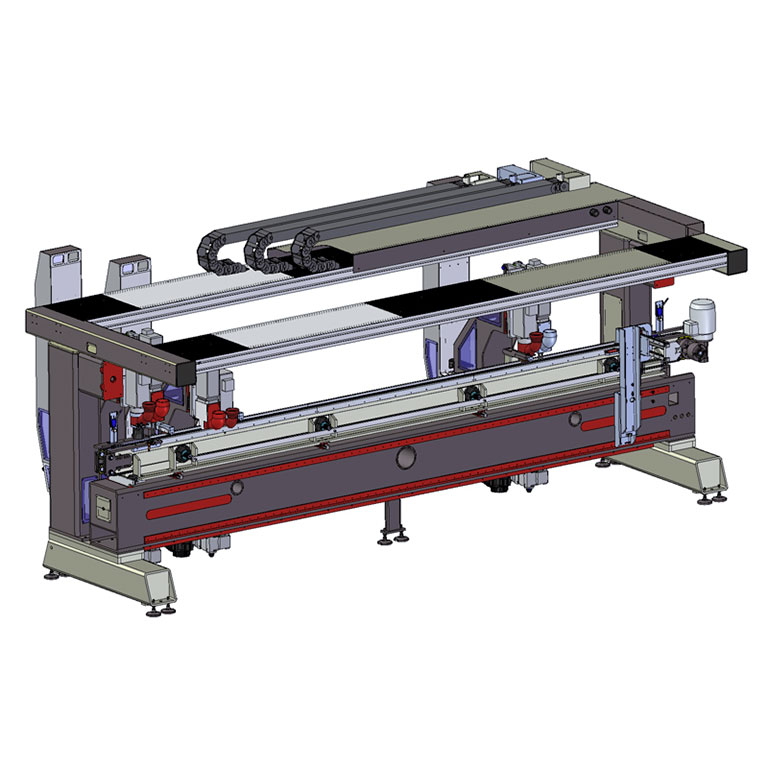

The fully automatic CNC work centers from Working | Process for the production of single pieces offer high production performance and quality. Discover the new EVO Executive 3555

In Working Process we do Mechatronics, electronics applied to mechanics.

No limits to the design of your wooden frames

Customized solutions for high production rate with flexibility.

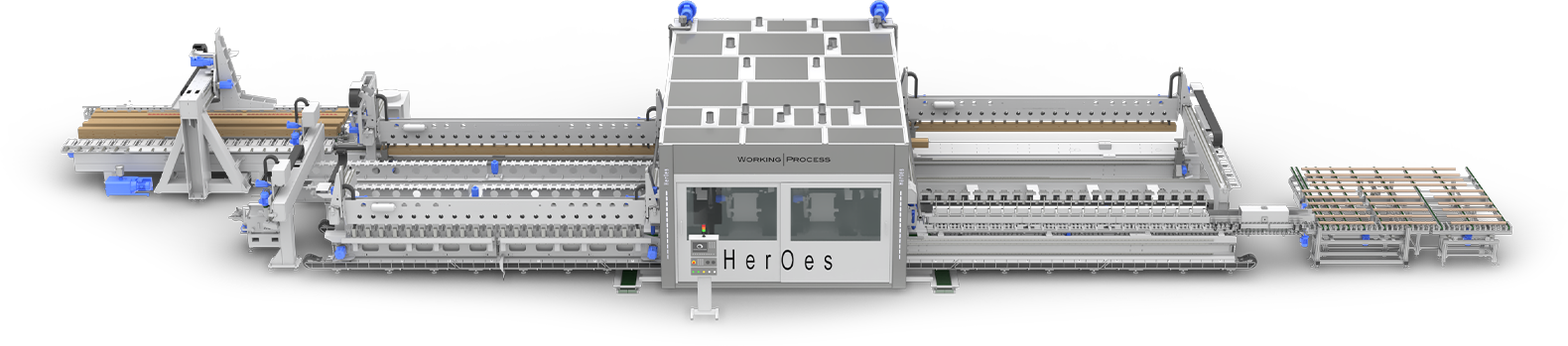

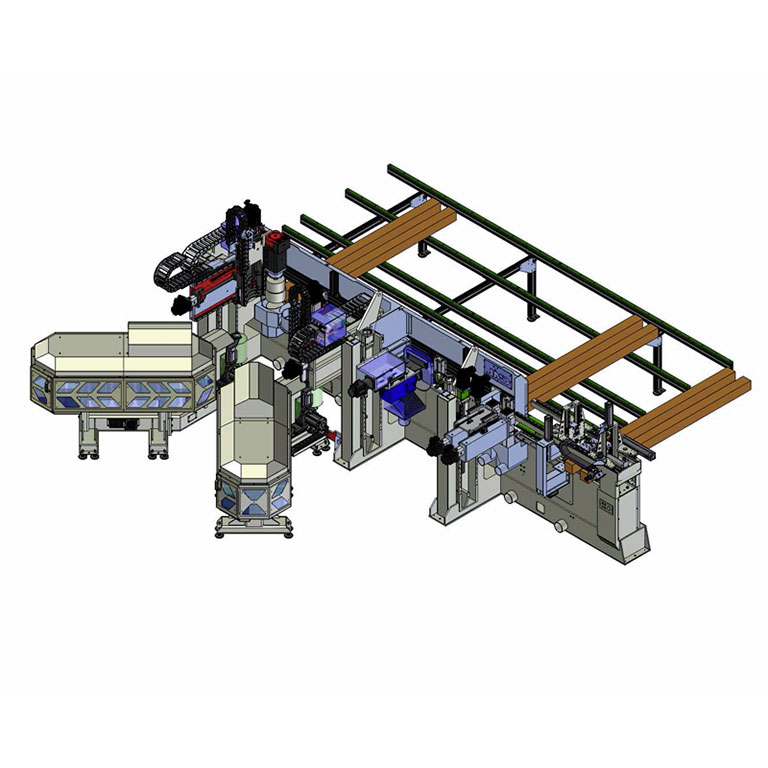

CML is a brand of Working | Process for bespoke industrial production systems that ensure maximum productivity.

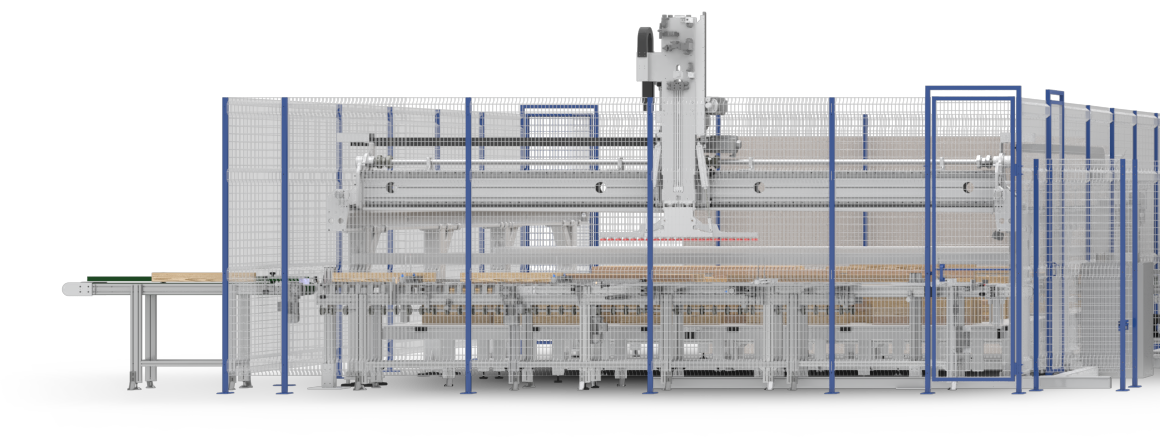

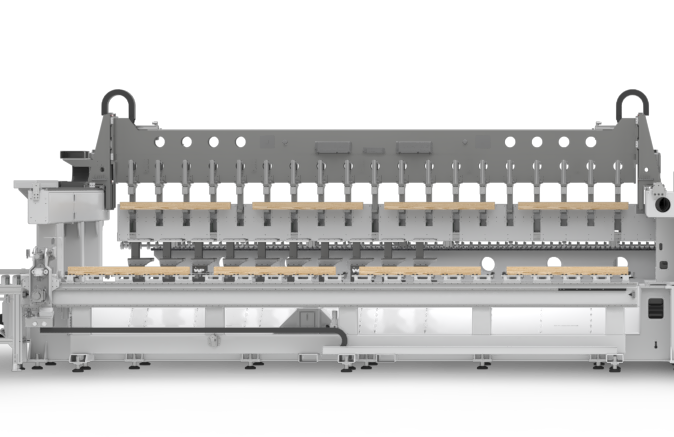

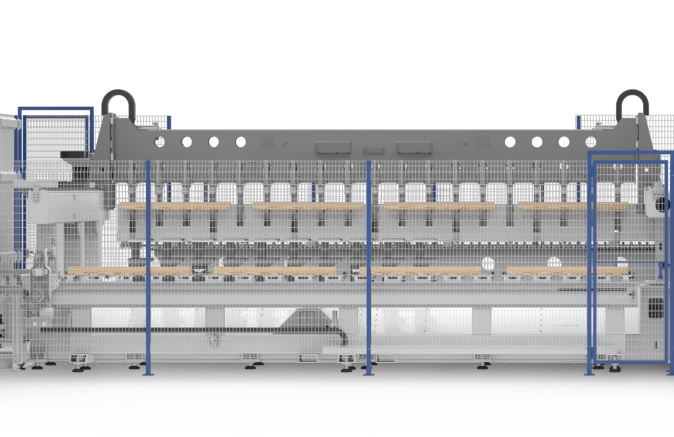

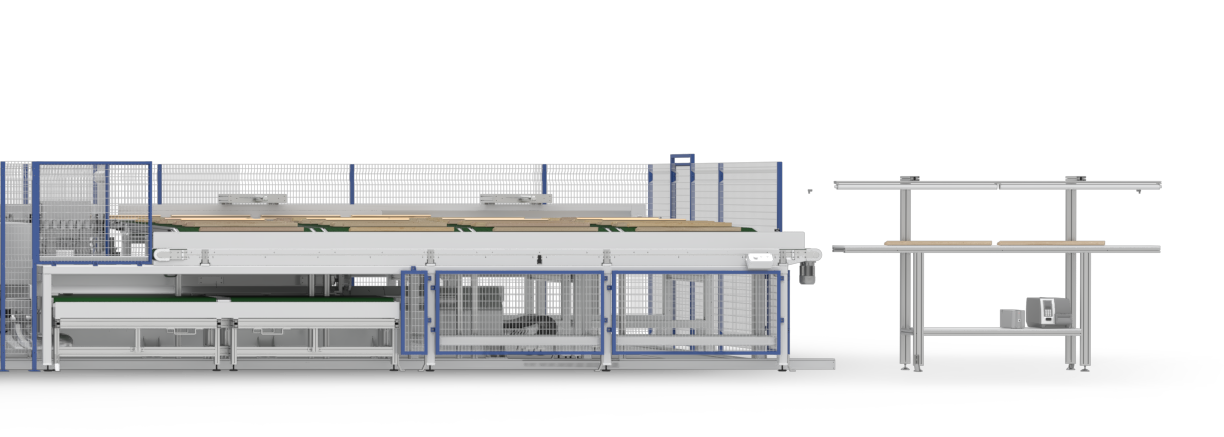

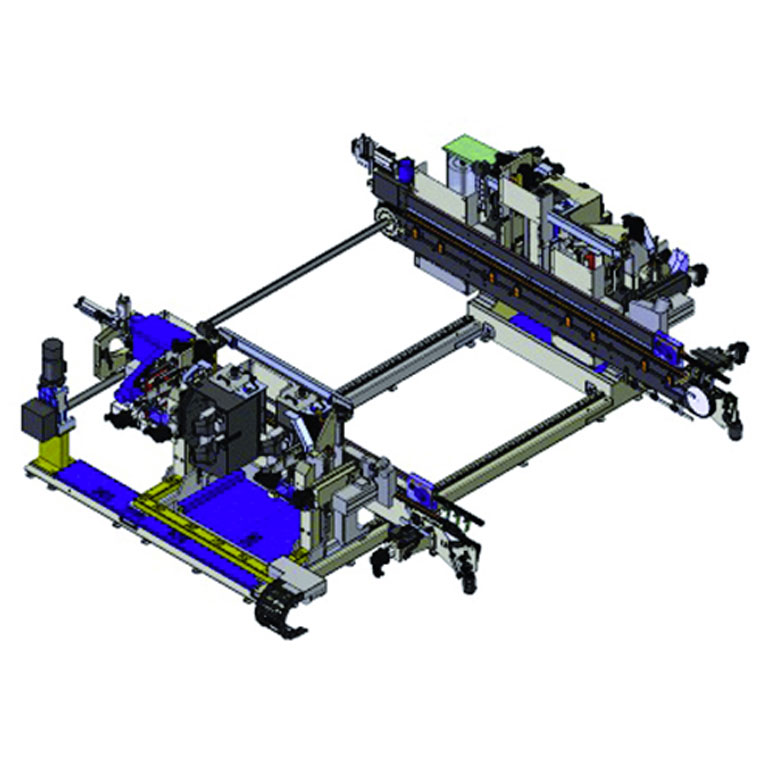

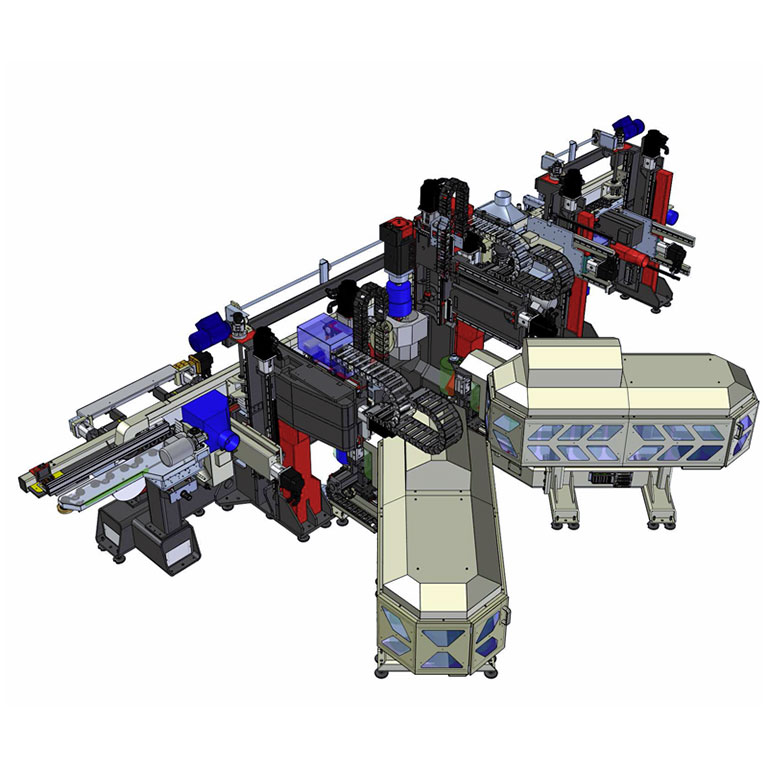

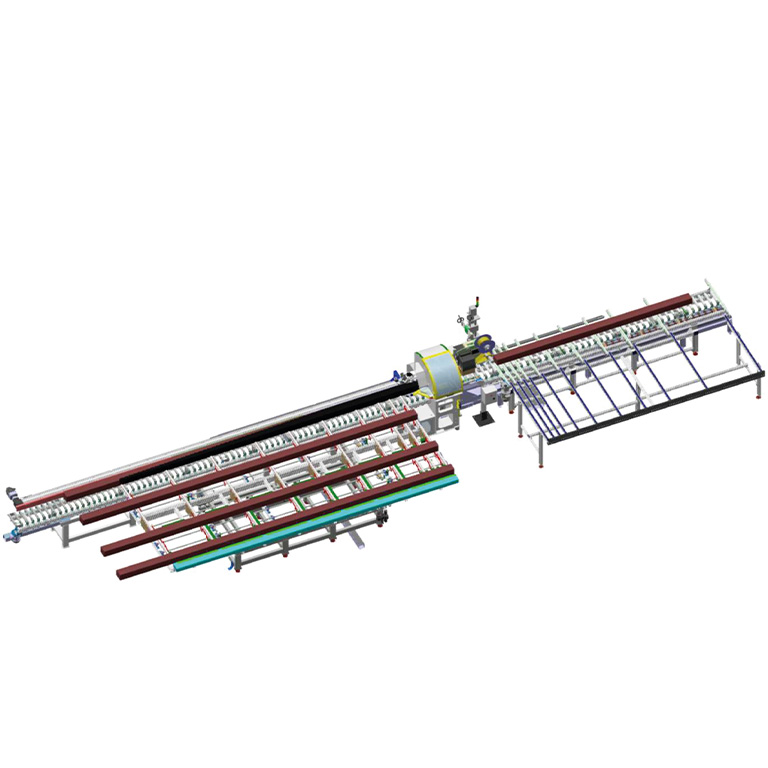

Our CML brand production lines are designed for custom production processes and high capacities, starting from 2 pieces per minute and beyond. They can be individually integrated into your company’s existing production lines. The result is an efficient and reliable system. Typical work process.

Create custom production processes with CML

Whether it’s Sq-1, Pro-1, Drillmatic, Step, Trl 700, or CML lines, the CML brand production lines are designed for high capacity. Just like the automatic loaders. They are all implemented after a thorough analysis based on the customer’s needs and are the best proof of our know-how in production processes.

The high-capacity production lines branded CML are designed and built based on customer requirements.

Discover all the CML modules to create your wooden window production line.

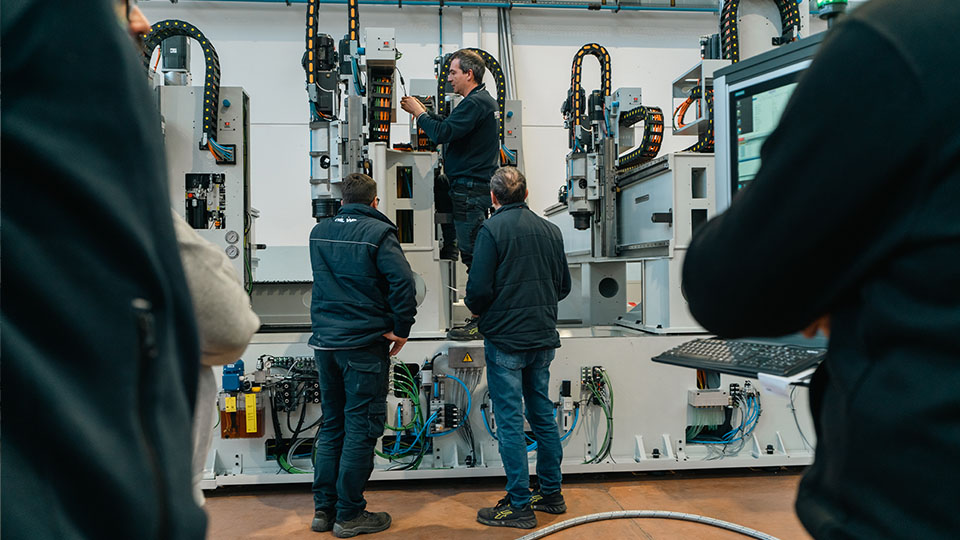

We do “Mechatronics”

We design and develop both the mechanical part of our machinery and the IT, logic and supervision parts. We exploit global knowledge and creatively employ all that is best in terms of material technologies, software, electronics… to create cutting-edge solutions for our partners and allow them to develop real competitive advantages in against its competitors.